When using the Profile Group Parameters dialog to set parameters for an Advanced Contour Mill Strategy, the following settings are available:

Tool Position — Set the position of tool in relation to the profile: On, Left or Right.

Cut Direction — Select whether or not the toolpath changes direction between axial steps.

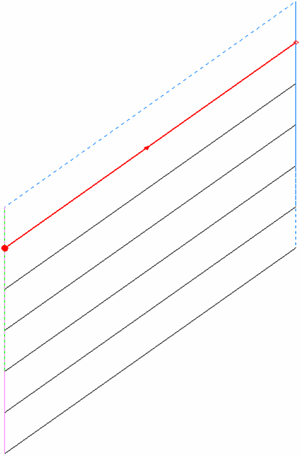

- Uni-Directional — Select this option so that after the tool completes a pass of the toolpath in one direction, the next pass in depth is in the same direction.

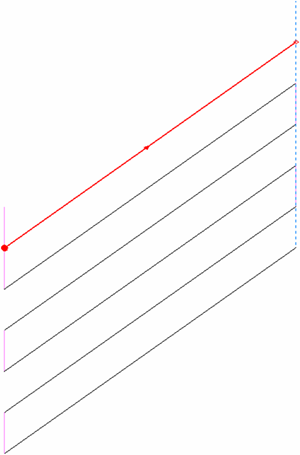

- Bi-Directional — Select this option so that after the tool completes a pass of the toolpath in one direction, the next pass in depth is in the reverse direction. This minimizes tool lift and travel.

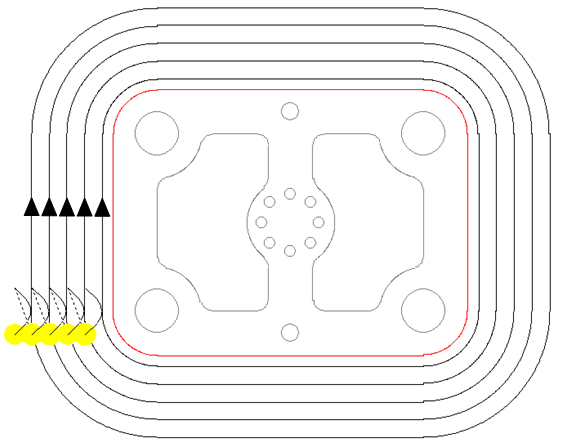

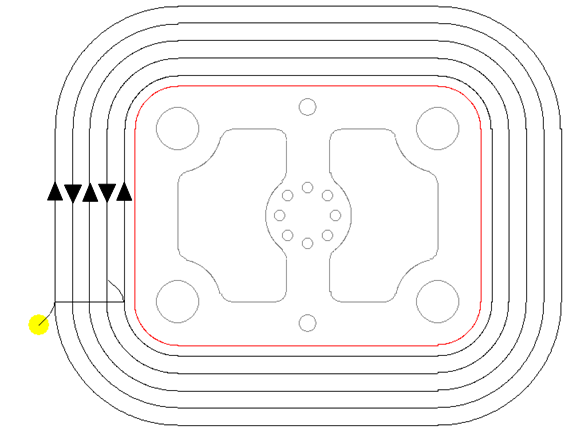

Toolpath Direction — Select whether or not the toolpath changes direction between radial steps:

- Uni-Directional — Select this option so after the tool completes a pass of the toolpath in one direction, the next pass over is in the same direction.

- Bi-Directional — Select this option so after the tool completes a pass of the toolpath in one direction, the next pass over is in the reverse direction. This minimizes tool lift and travel.

Define Block  — Click the Define Block button to display the Define Block dialog, where you can specify the limits (in X, Y, and Z) within which advanced milling is performed. You can define a Cylinder -Z block or Box block.

— Click the Define Block button to display the Define Block dialog, where you can specify the limits (in X, Y, and Z) within which advanced milling is performed. You can define a Cylinder -Z block or Box block.

Z_Surf (S) — Enter the signed distance from the zero reference point to the part surface.

Z_Depth (D) — Enter the depth of the operation to be performed.

Z_Rapid (R) — Enter the distance between the bottom tip of the tool and the part surface when a tool performs rapid moves.

Z_Clear (Cl) — Enter the distance between the bottom tip of the tool and the part surface when a tool starts feeding into the part.

Bottom Finish (b) — Enter the amount of material left on the bottom for finishing if the Finishing option is selected.

Wall Finish (w) — Enter the amount of material left on the wall for finishing if the Finishing option is selected. You can enter a positive or negative value.

Initial Stock (q) — Enter the thickness of the initial stock to be contoured.

Operations information

- Roughing — Select this option to include a roughing pass operation.

- Finishing — Select this option to include the finishing pass operation.

- Diam (d) — Enter the diameter of the tool used to perform the selected operations, for example Roughing and Finishing operations.

- Tool ID — Enter the ID of the selected tool. When you have saved the group, you can click the icon showing a representation of the tool (for example

) to display the Edit Tool dialog to view, or modify, details of the tool.

) to display the Edit Tool dialog to view, or modify, details of the tool. - Width of Cut — Enter the width of the cut for the operation. This value can be calculated as a percentage of the diameter of the tool selected for the operation or specified as an absolute value, depending on the Width of Cut and Width of Cut Value settings on the Defaults for Milling dialog.

- Axial Step — Enter the axial step of the tool. By default, PartMaker uses the Axial Step value specified in the tool's properties in the Tools Data dialog. If the axial step is set to zero, the material is removed in a single axial step.

- Options — Click the Options button to display the Advanced Contour Mill dialog, where you can define the parameters of your strategy.

Lock Toolpath —Select this option to lock the toolpath. When a toolpath is locked, PartMaker does not recalculate it even if its settings on the Profile Group Parameters dialog change. Deselecting this option unlocks the toolpath.

Polar Style Output — Select this option to specify whether the NC program is in polar format. This allows for Posts to explicitly support machining without polar interpolation activated in the NC code. This option is available only when using a Mill End, Polar Face window.

- When selected, the post will typically output X and Y positions with polar interpolation activated.

- When deselected, the Post will typically output Radius and C-angle positions without polar interpolation.

Group Name — Enter a name for the profile group.

Select Tools — Click to display the Select Tool dialog, where you can select the tool to use for machining.