Shell Element Property

Description: Defines the membrane, bending, and transverse shear properties of shell elements (CTRIA3, CTRIAR, CQUAD4, and CQUADR entries).

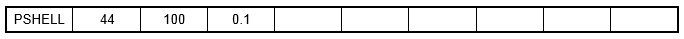

Format:

Example:

| Field | Definition | Type | Default | ||

|---|---|---|---|---|---|

| PID | Property identification number. | Integer > 0 | Required | ||

| MID1 | Material identification number for the membrane. | Integer > 0 or blank | |||

| T | Default membrane thickness for Ti on the connection entry. | Real or blank | |||

| MID2 | Material identification number for bending. | Integer ≥ -1 or blank | See Remark 18 | ||

| 12I/T3 | Bending stiffness parameter. | Real or blank | 1.0 | ||

| MID3 | Material identification number for transverse shear. | Integer > 0 or blank, must be blank unless MID2 > 0 | See Remark 18 | ||

| TS/T | Transverse shear thickness divided by the membrane thickness. | Real or blank | 0.833333 | ||

| NSM | Nonstructural mass per unit area. | Real or blank | 0.0 | ||

| Z1, Z2 | Fiber distances for stress computation. The right-hand rule and the order in which the grid points are listed on the connection entry determine the positive direction. | Real or blank | See Remark 10 | ||

| MID4 | Material identification number for membrane-bending coupling. See Remark 6. | Integer > 0 or blank, must be blank unless MID1 > 0, MID2 > 0, and MID3 > 0, may not equal MID1, MID2, or MID3 | |||

| THETA | Material property orientation angle in degrees. | Real or blank | See Remark 12 | ||

| MCID | Material coordinate system identification number. | Integer ≥ 0 | See Remark 12 | ||

| SDIR | Element stress component direction for tension-only element. See Remark 13. | 0 ≤ Integer ≤ 4 | 0 | ||

| SC | Compression allowable. Stress components, as defined by SDIR, less than this value will degenerate the element membrane stiffness to a shear panel. | Real | 0.0 | ||

| SFACTCX | Compression stiffness scale factor in the element x-direction. See Remark 14. | Real | 1.0E-10 | ||

| SFACTCY | Compression stiffness scale factor in the element y-direction. See Remark 14. | Real | SFACTCX | ||

| RTYPE | Reversion element type. See Remarks 15 and 16.

|

1 ≤ Integer ≤ 2 | 1 | ||

| F1 | Effectiveness factor for extensional stiffness along edge 1-2. See Remark 17. | Real ≥ 0.0 | 0.0 | ||

| F2 | Effectiveness factor for extensional stiffness along edge 2-3. See Remark 17. | Real ≥ 0.0 | 0.0 | ||

| F3 | Effectiveness factor for extensional stiffness along edge 3-4. See Remark 17. | Real ≥ 0.0 | F1 | ||

| F4 | Effectiveness factor for extensional stiffness along edge 4-1. See Remark 17. | Real ≥ 0.0 | F2 |

Remarks:

- All PSHELL property entries must have unique identification numbers.

- The translational structural mass is computed from the membrane material density and rotational mass from the bending material density.

- PSHELL entries may reference MAT1, MAT2, or MAT8 material property entries. If element reversion to a full shear panel element is specified in a nonlinear solution and a MAT2 or MAT8 material is referenced, PARAM, SHEARELEMTYPE must be set to NORAN or AUTO or a fatal error will be issued.

- If the transverse shear material, MID3, references a MAT2 data entry, then G13, G23, and G33 must be zero or blank.

- The results of leaving an MID field blank are:

MID1 No membrane or coupling stiffness. MID2 No bending or coupling stiffness. MID3 No transverse shear stiffness or coupling stiffness. MID4 No membrane-bending coupling unless ZOFFS is specified on the connection entry. See Remark 6. Note: MID1, MID2, and MID3 must be specified if the ZOFFS field is also specified on the connection entry. - The MID4 field should be left blank if the material properties are symmetric with respect to the mid-surface of the shell. If the element centerline is offset from the plane of the grid points but the material properties are symmetric, the preferred method for modeling the offset is by use of the ZOFFS field on the connection entry. Although the MID4 field may be used for this purpose, it may produce ill-conditioned stiffness matrices (negative terms on factor diagonal) if done incorrectly.

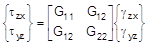

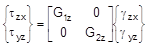

- If MID3 references an isotropic material via a

MAT1 entry:

- If MID3 references an anisotropic material via a

MAT2 entry:

- If MID3 references an orthotropic material via a

MAT8 entry:

- The default for Z1 is -T/2, and for Z2 is +T/2. T is the local plate thickness, defined either by T on this entry, or by membrane thickness' at connected grid points, if they are input on connection entries.

- For plane strain analysis, set MID2 = -1 and set MID1 to reference a MAT1 entry.

- THETA/MCID is used only if field 8 of the CQUAD4 or CQUADR, or field 7 of the CTRIA3 or CTRIAR entry is blank. If field 5 of the PSHELL continuation is also blank, then THETA = 0.0 is assumed when a non-isotropic material is referenced.

- The SDIR field specifies which element stress component direction should be used when determining if the element has failed and should revert to a shear panel.

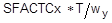

SDIR Description 0 Standard tension/compression shell element 1 Use the element membrane normal-x stress 2 Use the element membrane normal-y stress 3 Use either the element membrane normal-x or normal-y stress 4 Standard shear panel element - The SFACTCi scale factors are applicable when RTYPE = 1 and are used to reduce the membrane stiffness of the reverted tension-only element. The default value will revert the element membrane contribution to tension-only while a value of 1.0 will result in no change in behavior (standard shell element). Intermediate values provide for some compressive load carrying capability in the element. Values greater than 1.0 are normalized relative to the element width (CQUAD4/CQUADR elements only). For example in the element x-direction the scale factor used is

.

.

- The RTYPE setting determines the element type after reversion. The default value of 1 will revert the membrane portion of the element to tension-only behavior with limited compressive load carrying capability determined by the SFACTCi settings. If PARAM, FIXNLTOQUAD is set to OFF and the element load state changes back to tension, the element will revert back to a normal shell element. When RTYPE is set to 2, the element reverts to a full shear panel with the extensional stiffness defined by the effectiveness factors, Fi and no bending or transverse shear capability. With this setting once the element has reverted it will remain a shear panel regardless of the PARAM, FIXNLTOQUAD setting.

- Element reversion to tension-only behavior requires a nonlinear solution. Tension-only behavior may be disabled by setting PARAM, NLTOQUAD to OFF (default is ON).

- The Fi effectiveness factors are applicable when RTYPE = 2 and the element has reverted to a full shear panel element (CSHEAR). The effective extensional area is defined by means of equivalent rods on the perimeter of the element. If F1 ≤ 1.01, the area of the rod on edge 1-2 is set equal to (F1*T*PA)/(L12+L34) where PA is the panel surface area and L12, L34 are the lengths of sides 1-2 and 3-4. Thus, if F1 = F3 = 1.0, the panel is fully effective for extension in the 1-2 direction. If F1 > 1.01, the area of the rod on edge 1-2 is set equal to 0.5*F1*T2. The rod material used is the same as the parent element. In the case of an orthotropic material (MAT8) E1 will be used for F1 and F3 and E2 for F2 and F4.

- The default for the MID2 and MID3 fields is MID1 when MID1 is a nonlinear material.