Layered Composite Solid Element Property

Description: Defines the global plies and properties of an n-ply composite material laminate for CHEXA and CPENTA solid elements.

Format:

Example:

| Field | Definition | Type | Default | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PID | Property identification number. | Integer > 0 | |||||||||||||

| MCID | Identification number of the material coordinate system. See Remarks 5 and 6. | Integer ≥ -1 or blank | See Remark 5 | ||||||||||||

| XZDIR | Ply orientation reference material axis and element orientation, one of the following character variables: 12, 13, 21, 23, 31, or 32. See Remark 6. | Integer | 13 | ||||||||||||

| SB | Allowable inter-laminar shear stress of the bonding material (allowable interlaminar shear stress). Required if bond shear failure index/strength ratio is desired. | Real > 0.0 | |||||||||||||

| NB | Allowable inter-laminar normal stress of the bonding material. | Real > 0.0 | |||||||||||||

| TREF | Reference temperature. See Remark 4. | Real | 0.0 | ||||||||||||

| GE | Structural element damping coefficient. See Remarks 12 and 13. | Real | 0.0 | ||||||||||||

| GPLYIDi | User defined global ply identification number. | Integer > 0 | Ply number | ||||||||||||

| MIDi | Material identification number of the various plies. The plies are identified by serially numbering them from 1 at the bottom layer. The MIDs must refer to MAT1, MAT8, MAT9, or MAT12 Bulk Data entries. See Remark 11. | Integer > 0 | |||||||||||||

| Ti | Ply thickness. See Remarks 2 and 7. | Real or blank | T1 required | ||||||||||||

| THETAi | Orientation angle of the longitudinal direction of each ply with the material axis of the element. The plies are numbered serially starting with 1 at the bottom layer. The bottom layer is defined as the surface with the largest -Z value in the element coordinate system. See Remark 6. | Real or blank | 0.0 | ||||||||||||

| PLYFTi | Ply failure theory. The following theories are allowed. (If blank and not specified on the referenced MIDi entry, then no failure calculation is performed.)

|

Character or blank | |||||||||||||

| ILFTi | Inter-laminar failure theory. The following theories are allowed. (If blank, then both calculations are performed.)

|

Character or blank | Both | ||||||||||||

| SOUTi | Stress or strain output request, one of the following character variables: YES or NO. | Character | NO |

Remarks:

- The global ply identification number should be unique with respect to all other global plies.

- The default for MID2, …, MIDn is the last defined MIDi. In the example above MID1 is the default for MID2, MID3, and MID4. The same logic applies to Ti.

- The global ply identification number (GPLYIDi) and at least one of the four values (MIDi, Ti, THETAi, SOUTi) must present for a ply to exist. The minimum number of plies is one.

- When PARAM, TEMPDEPCOMP is set to OFF (default is ON) the TREF given on the PCOMP entry will be used for all plies of the element and will override values supplied on material entries for individual plies. If the PCOMP entry references temperature-dependent material properties, then TREF given on the PCOMP will be used as the temperature to determine material properties and TEMPERATURE Case Control commands will be ignored for deriving the equivalent PSHELL and MAT1entries used to describe the composite element. (See Section 5, Parameters, for more information on TEMPDEPCOMP.)

- See the CHEXA, CPENTA, CPYRA, or CTETRA entry for the definition of the element coordinate system. The material coordinate system (MCID) may be the basic system (0), any defined system (Integer > 0), or the element coordinate system (-1 or blank). The default for MCID is the element coordinate system.

- The ply orientation is relative to the element material x-direction similar to that of a composite shell element. By default the element material x-direction is defined by projecting the MCID x-axis onto a surface defined by the element z-axis. The MCID y-axis or z-axis may be specified using the first component number of the XZDIR field. The element z-axis can be reoriented using the second component number of the XZDIR field. The element z-axis also defines the element thickness direction. Only CHEXA and CPENTA elements may be referenced if the property defines a layered solid element.

- The laminate thickness is adjusted at the corners to coincide with the distance between grid points. The thickness of each ply in the laminate is adjusted proportionally.

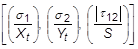

- When PARAM, COMPILSMETHOD is set to COMPONENT (default), the failure index for the bonding material is calculated as Failure Index = max(

). (See Section 5,

Parameters, for more information on

COMPILSMETHOD.) The Failure Index for the ply is calculated as shown in the table below.

). (See Section 5,

Parameters, for more information on

COMPILSMETHOD.) The Failure Index for the ply is calculated as shown in the table below.

Theory Failure Index Remarks Hill

Orthotropic materials with equal strengths in tension and compression. Hoffman

Orthotropic materials under a general state of plane stress with unequal tensile and compressive strengths. Tsai-Wu

Orthotropic materials under a general state of plane stress with unequal tensile and compressive strengths. MCT See the Autodesk Nastran User's Manual, References 20, 21, and 22. Orthotropic materials comprised of unidirectional plies or plain weave fabric under a general state of plane stress. Max Stress Max

None Max Strain Max

None - The STRENGTHRATIO model parameter is used to request the output of the Tsai Strength Ratio (R) instead of Failure Index. (See Section 5, Parameters, for more information on STRENGTHRATIO.)

- A function of this entry is to derive equivalent internal PSHELL and MATi entries to describe the composite element. These equivalent entries are given in the database definition section of the Model Results Output File and in the translated Bulk Data Output File.

- This entry may only be used to define a layered solid element. The MIDi fields may only reference MAT1, MAT8, MAT9, or MAT12 entries.

- To obtain the damping coefficient GE, multiply the critical damping ratio C/C 0, by 2.0.

- If PARAM, W4 is not specified, GE is ignored in transient response analysis. (See Section 5, Parameters, for more information on W4.)

- To compute a ply and/or bond failure index/strength ratio, the

STRESS or

STRAIN Case Control command must be present, SOUTi must be set to YES, and the following must be defined:

- For a ply stress or strain failure index/strength ratio:

- PLYFTi on the PCOMPS or referenced MIDi entry

- The stress or strain allowables on the referenced MIDi entry

- For a bond failure index/strength ratio:

- The stress allowables SB and/or NB on the PCOMPS or referenced MIDi entry

- For a ply stress or strain failure index/strength ratio:

- Ply stress and strain results are always computed in the ply coordinate system.