You can index around the Z axis for 2.5D machining, using, for example, a rotary table lying flat on a vertical milling machine. This means that you can mill large parts that exceed the travel of the machine in one direction, by milling them in stages.

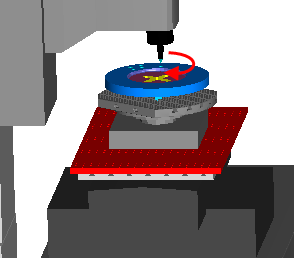

This example shows a part being machined with no multi-axis positioning. When drilling holes near the edges of the part, the machine moves a lot in the X and Y directions:

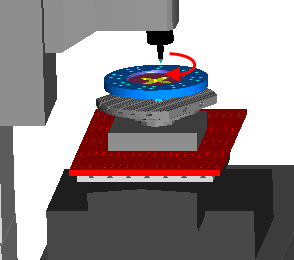

And risks a collision at point  :

:

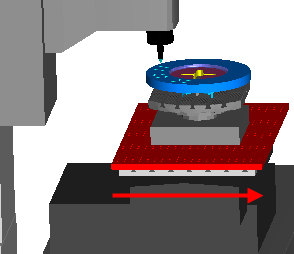

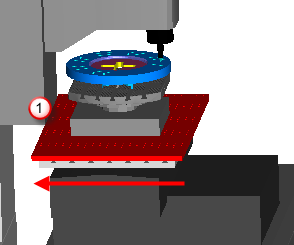

By selecting 4th Axis Positioning and Index around the STOCK Z Axis, you can cut the holes by rotating around the Z axis:

|

|

|