The following 5-axis machine types are supported by FeatureCAM.

Table on table machines

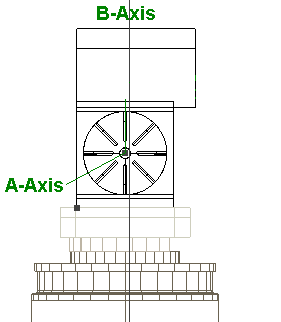

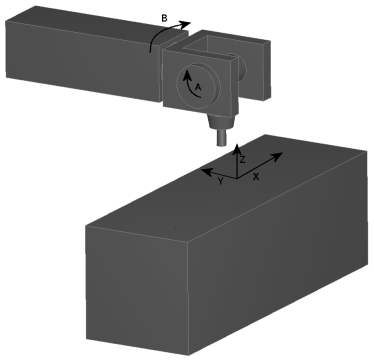

Horizontal with stacked tables — These horizontal milling machines rotate about the Y-axis, then around the X-axis. They are also called B over A machines.

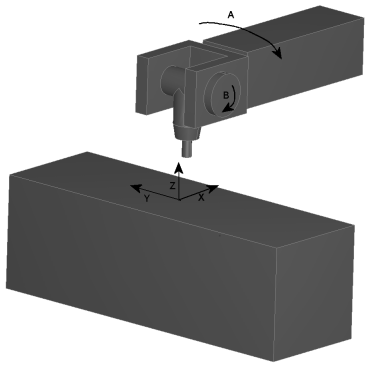

Vertical with stacked tables — These machines are vertical mills that rotate about X-axis then around the Y-axis. These machines are also known as A over B machines.

Machines with tilting heads

FeatureCAM supports tilting-head machines that have the following two capabilities:

3D coordinate transforms — The control must allow programming of 2.5D features in the X and Y planes. This means that the depths of features are always in the Z or -Z directions.

Tool length offset — The touch-off point (or zero point) of the tool must move with the rotated tool.

The machine architectures supported are as follows:

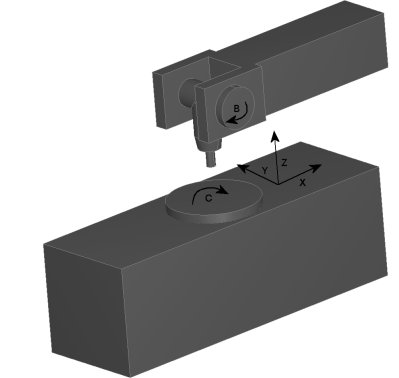

C rotary table and B tilting head — These machines rotate about Z and then the head rotates around the Y-axis.

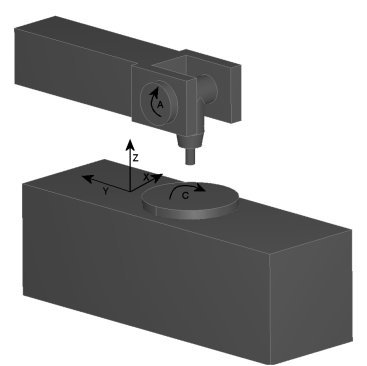

C rotary table and A tilting head — These machines rotate about Z and the head rotates around X.

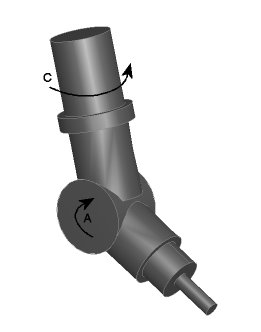

C swiveling and A tilting head — These machines rotate around Z with a table and then the head tilts around the X axis. They are also known as gimbal heads.

B and A tilting head — Rotates about Y using a table and then X in the head.

A and B tilting head — Rotates about X using a table and then Y in the head.

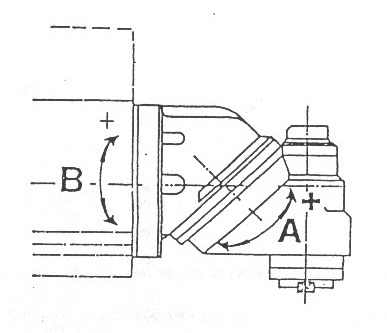

B and 45 Degree angled A tilting head — Rotate about Y, then rotate about X with a head that is angled by 45 degrees. This head is also known as a huron head.

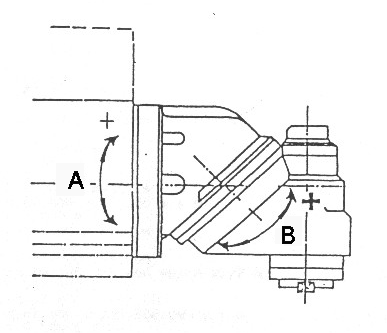

A and 45 degree angled B tilting head — Rotate about X, then about Y with a head that is angled by 45 degrees. Also known as a huron head.

See machine dimensions for specific machine parameters.