5-axis positioning enables you to mill 2.5D or 3D toolpaths at 5-axis orientations.

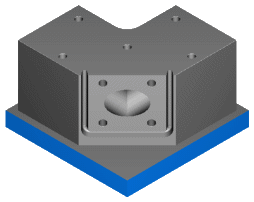

5-axis positioning provides a convenient method of manufacturing parts that require milling on multiple faces by minimizing setups. The image below shows an example of a part that requires milling from four different orientations. With 5th-axis positioning, the whole part can be milled with a single program.

FeatureCAM provides two types of 5-axis positioning NC programs. The first method requires the operator to set only a single coordinate system. The entire program is then generated with regard to this coordinate system. The advantage of this method is that it minimizes the setup time. The disadvantage is that the resulting NC programs are harder to read because the coordinates for milling each face are rotated.

The second method uses standard fixture offsets to determine the coordinate system for each face. The advantage of this method is that the code for each face is easier to read. The disadvantage is that the operator must touch-off each face.