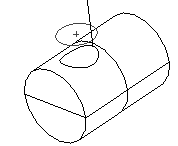

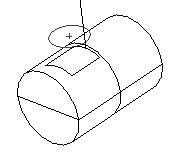

Arcs that are wrapped must be converted to small 3D line segments. The Wrap tolerance is used to determine the acceptable distance between the line segments and the initial arc. The figure on the left shows a lower tolerance for a wrapped circular groove. The right-hand figure shows a large tolerance. In this case the circle is approximated by a square.

The Wrap tolerance is also used to calculate toolpaths which are on a cylinder, given a linear toolpath in unwrapped space. That is, if the toolpath without wrapping is a straight line, then the wrapped toolpath is an arc around the index axis. The Wrap tolerance controls the accuracy of this arc.

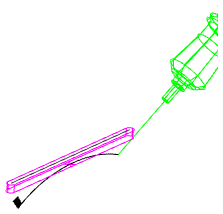

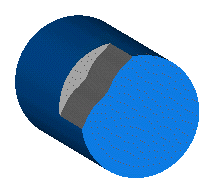

This attribute is also used to control the polar interpolation on face cuts for turn/milling. If FeatureCAM is performing the polar interpolation, any linear move or off center arc move on the face of the part must be interpolated by linear moves and rotations about the C axis. Wrap tolerance is used to control the fineness of this linear interpolation. The figure on the left shows a straight face cut with loose wrap tolerance. The right-hand figure shows the same cut with a tighter tolerance.

When circular interpolation is turned off in post, then Wrap tolerance is used to control fineness of toolpath.