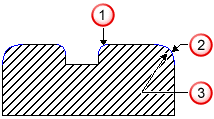

A Round feature creates an edge break along a curve with a rounding tool.

— Inside

— Inside

— Outside

— Outside

— Radius

— Radius

The shape of the Round is defined by a curve. Select more than one curve if you want to create a Round along multiple curves with one feature. The curves can be open (the ends do not touch) or closed (the beginning and the end points are the same).

In general, FeatureCAM uses the following process to create a Round feature:

- Conducts an analysis of the curve and based on the specified radius of the round and on the tightest bend in the curve, using corner radius and inner diameter of the rounding tool as the tool selection criteria, selects a tool from the current tool crib.

- For corner radius, FeatureCAM picks a tool that has exactly the same corner radius as the Round feature.

- For inner radius, FeatureCAM analyzes the curve that defines the rounds and determines the tool that fits into the tightest corners of the curve.

- Chooses feeds and speeds using the Feed/Speed database that you can customize. Feeds and speeds are determined based on the stock material.

- Generates a roughing pass. The important aspects of roughing are as follows:

- Getting to depth — The tool must get to depth and this is accomplished by plunging.

- Vertical step — There is no vertical step, but the horizontal step size is controlled by the Distance between cuts attribute on the Stepoverstab.

- Finish allowance — The rough pass contains a Finish allowance attribute which controls how much material to leave for the finishing pass. By default this is 0.02.

- If activated, generates a finish pass. By default, the finish pass is turned off and the entire feature is machined by the roughing pass. This can be changed on the

Strategy page.

The important aspects of finishing are:

- Tool selection — After roughing, the roughing tool is used to finish the round. Use Finish Tool commands FeatureCAM to choose a separate finishing tool (that has the same characteristics unless you override them).

- Vertical Step — There is no vertical step, but the horizontal step size is controlled by the Distance between cuts attribute on the Stepovers tab.

- Finish passes and overlap — The tool goes around the Round a number of times set by Finish passes, and overlaps the starting point by an amount controlled by Finish overlap.

- Retract — Removes the tool from the stock area and sets up for the next operation.

You can edit this process in these places:

- To edit all instances of this type of feature in the current document, use the Machining Attributes dialog.

- To edit a single feature, use the Tools, Milling, Strategy, and Misc. tabs for the feature in the Feature Properties dialog.

The tooling database also has a large impact on how a feature is machined, and the feed/speed database helps to determine the feeds and speeds used.