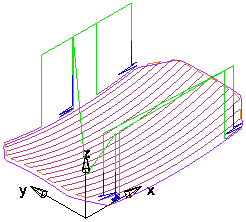

X parallel — Select this option to cut parallel to the X axis.

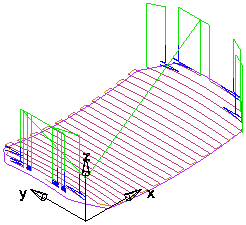

Y parallel — Select this option to cut parallel to the Y axis.

Automatic — Select this option to let FeatureCAM determine the most appropriate angle for each region of the feature.

Parallel angle — Optionally enter an angle in degrees. You can have the toolpath at any angle. The angle is measured counter-clockwise from the X axis if X parallel is selected or counter-clockwise from the Y axis if Y parallel is selected.

Add perpendicular remachining pass — Select this option if you want to add a perpendicular, remachining pass. For example, this setting adds a Y parallel pass to an X parallel operation. To use this option you also must specify the Steep slope angle.

Optimize parallel pass — If you create a parallel toolpath and select

Add perpendicular remachining pass, with a

Steep slope angle greater than

0 , the

Optimize parallel pass option trims the parallel pass so it doesn't machine the areas that the perpendicular pass machines.

, the

Optimize parallel pass option trims the parallel pass so it doesn't machine the areas that the perpendicular pass machines.

Steep slope angle — This option is used with Add perpendicular remachining pass. The perpendicular pass is applied only to regions that exceed this slope limit.

Remachining — Click this button to open the Remachining dialog.

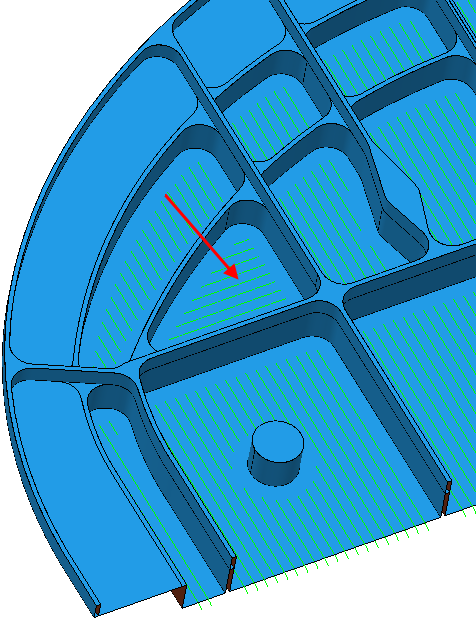

Holder collision clipping — Clips the toolpath where the holder or shank collides with a part surface, check surface, or unmachined stock. When selected, the Holder clearance and Shank clearance attributes are displayed on the Milling tab for the operation.

Machine maximum stock — Use with Holder collision clipping to machine the stock as close to the part without causing a holder collision. This creates smoother toolpaths with fewer retracts, which can improve the surface finish and reduce the machining time, but may cause increased air cutting on some parts.