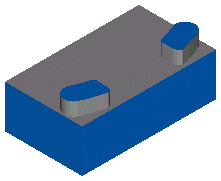

The top boss of this brake caliper is used in this example.

When cutting this feature in aluminum with the default stepover and feed/speed table, the horsepower is estimated at 2.0 for the roughing pass and 0.3 for the finishing pass. A 0.5" tool is selected. In this example, the maximum horsepower should be less than 2.5. When a tool load is run on this example, the maximum horsepower required is shown to be 5.9. To stay under the stated horsepower requirement, the feedrate for the roughing pass must be reduced by 50%. Without feedrate optimization, your only choice for lower the horsepower requirements are to adjust the width or depth of cut for the entire operation or change the feedrate for the entire operation.

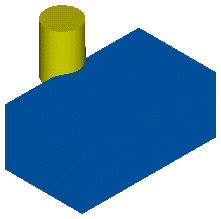

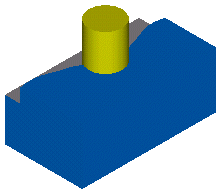

When you examine the toolpaths of this boss there are light cuts, as shown in the narrow cut in the first image, and heavy cuts, as shown in the wide cuts in the second image.

Feedrate optimization looks at the tool load for each move and adjusts the feedrate to even out the load. Instead of reducing the overall feedrate for the roughing pass, you can keep the feedrate for the roughing feature the same and use feedrate optimization to adjust the feedrates of the individual moves of the toolpath. The table below shows that feedrate optimization allowed us to reduce the machining time by 47% while maintaining a more constant cutter load.

|

Before Feedrate Optimization |

After Feedrate Optimization |

|

|

Roughing |

2:57 |

1:21 |

|

Finishing |

0:30 |

0:27 |

|

Total |

3:27 |

1:49 |

|

Time Savings |

47% |

|

|

Max Horsepower |

2.4 |

2.4 |