You can use Feed Optimization to even out the tool load by adjusting the program's feed rates.

To optimize a program's feed rates:

- Generate the toolpaths.

- Set the Target horsepower milling attribute for the operations you would like to optimize. For 2.5D finish milling operations, set the Peripheral Feed options.

- Select Features & Manufacturing tab > Materials panel > Optimize Feeds > Optimize Feeds.

- Specify the Feed Optimization parameters, and click OK to close the dialog.

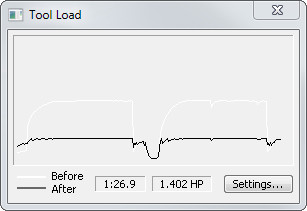

- Select Home tab > Simulation panel > Show > Tool Load, and run the simulation again to show the

tool load before and after the optimization. The

Tool Load graph shows the optimized loads in black and the unoptimized loads in white:

In the image above, the tool load spikes have been reduced in the black (optimized) curve.

- To remove the optimized feed rates without regenerating the NC code, select Features & Manufacturing tab > Materials panel > Optimize Feeds > Clear Optimized Feeds.