The tool is at a fixed angle relative to the direction of the toolpath. You can specify two different angles, Lead and Lean. If you specify a Lead angle and a Lean angle, the Lead Angle is applied first in the direction of the move, and then the Lean Angle from this rotated position towards a vector perpendicular to the move.

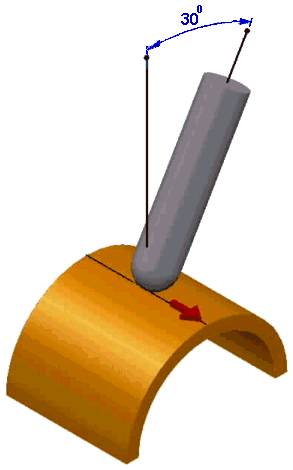

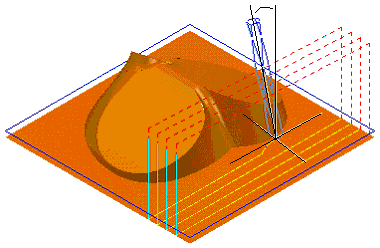

Lead Angle — This defines a rotation of the tool axis in the direction of travel. It is measured from the perpendicular to the direction of travel; 0 is vertical. Typically this is used to avoid cutting at the center of a ball nosed tool on flattish areas. The diagram below has a lead of 30 .

.

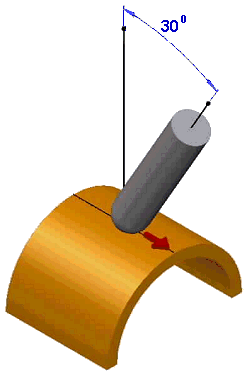

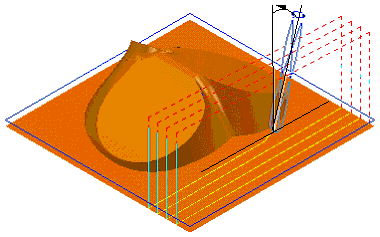

Lean Angle — This defines a rotation of the tool axis at right angles to the direction of travel; 0 is vertical. The diagram below has a lean of 30 degrees. Typically this is used to avoid collisions (such as a step). Or this can be used when machining up to a step to allow you to use a smaller tool.