5-axis machine tools do not guarantee (and frequently don't use) a straight line move from one point to another in multi-axis. This means that you cannot necessarily guess where the tool might move to between two points. The machine tool moves all of its axes simultaneously — it doesn't just move in X and then rotate the head. It does both together so that both movements are carried out at the same time. This is not a big issue if the points are close together. However, if the points are far apart, the machine tool (which may be rotating the tool tip between two points) can cause gouges when the part is cut on the actual machine.

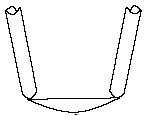

Consider moving between two points. Although the move looks like a straight line, it won't necessarily be a line on the machine tool.

Arc swept by machine tool.

FeatureCAM does attempt to linearize moves by dividing the curves into smaller straight line moves, based on the Use linearization and Inch/Metric Tolerance options on the Multi-axis dialog in XBUILD.

A small wrapping tolerance tends to make 3D and machine simulation slow. For this reason, the simulation has its own Linearization tolerance option, which you can set to a larger number than that of manufacturing. That is, the simulation uses the tolerance (which you set on the Options > Simulation > 2D/3D Shaded page) for linearization, and the posting process uses the wrap tolerance found on the Machine Attributes dialog.