A Step Bore feature is a series of nested circular pockets. You can specify a Step Bore, step by step, or use a number of concentric circles as the part's curve where each circle defines a level's diameter.

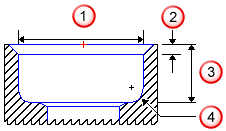

— Diameter

— Diameter

— Chamfer

— Chamfer

— Depth

— Depth

— Radius

— Radius

FeatureCAM follows this general process to create a Step Bore feature:

- Conducts an analysis of the curve and using tool diameter and length as the selection criteria, and from the current tool crib selects the tool to use.

- For tool diameter, the largest tool that can cut the step without gouging is selected.

- For tool length, FeatureCAM picks a tool that has flutes long enough to cut to the bottom of the Step Bore depth for that level.

- FeatureCAM chooses feeds and speeds for all of its milling using the Feed/Speed database that you can customize. Feeds and speeds are determined based on the stock material.

- Generates a roughing pass possibly in multiple Z steps depending on the depth of the step.

The important aspects of roughing are:

- Getting to depth — The tool must get to depth, and this can be accomplished by a zigzag in Z (the default setting and influenced by Max ramp angle), by plunging, or by pre-drilling.

- Vertical step — FeatureCAM's cut depth is no more than 100% of the tool radius.

- Horizontal stepover — FeatureCAM moves over laterally a percentage of the tool diameter (controlled with Rough pass %), as it steps across the feature.

- Finish allowance — Controls how much material to leave for the finishing pass. By default this is 0.02.

- Generates a finishing pass. By default, the bottom is not finished. The roughing tool removes all of the material in Z. This is controlled by

Finish bottom. Setting the

Single Point Bore option for a step disables the other finishing options.

The important aspects of finishing are:

- Tool selection, after roughing, the roughing tool is used to finish the Step Bore unless it is finished as a Single Point Bore. Use finish tool commands FeatureCAM to choose a separate finishing tool (that has the same characteristics unless you override them).

- Ramp on has the finish pass ramp into the material with an arc equal to a percentage of the tool diameter. Disabled for a Single Point Bore finish operation.

- Finish passes and overlap has the tool go around the step a number of times set by Finish passes, and overlaps the starting point by an amount controlled by Finish overlap.Disabled for a Single Point Bore finish operation.

- Ramp off uses another arc of the same size as the ramp on to move the tool away from the finished wall. Disabled for a Single Point Bore finish operation.

- Retract removes the tool from the stock area and sets up for the next operation.

Note: A Step Bore feature initially has two steps. Delete the second step and enter the dimensions for your round hole as the first step.

You can edit this process in these places:

- To edit all instances of this type of feature in the current document, use the Machining Attributes dialog.

- To edit a single feature, use the Tools, Milling, Strategy, and Misc. tabs for the feature in the Feature Properties dialog.

The tooling database also has a large impact on how a feature is machined, and the feed/speed database helps to determine the feeds and speeds used.