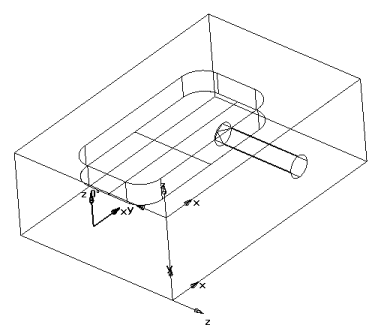

Normally each Setup generates a separate program. If the Setups of your part are a simple rotation around your machine's fourth axis as shown below you can use indexing to combine all the Setups into a single program that rotates each Setup into position using the 4th axis.

Indexing can be performed around the X or Y axis of the stock axis. The post processor you use must have the same indexing axis as your part. For each Setup the corresponding axis must be parallel to the indexing axis. For example, if you are indexing around the world coordinate X axis, the X axes of each Setup must be parallel to the stock axis.

When using indexing, the part documentation is combined for all Setups. This means that you have just one operations list, one tool list, and one NC part program for all Setups.

When positioning features, use the XYZ or polar types of positioning.