The Offset Method attribute controls whether the offsetting of the wire path is performed on the machine using cutter compensation or by FeatureCAM. Select Cutter comp to perform the offsetting on the machine, or Offset Toolpath if you want FeatureCAM to perform the offsetting.

To cut a workpiece to the finished size the Wire radius compensation function on the NC-machine is normally used. Activating this function with a particular value causes the machine to calculate a new path for the center of the wire. The compensation value is normally composed of the wire radius plus the spark gap allowance plus any finishing allowance that may be required. The compensation value is normally entered in a Compensation Register on the machine.

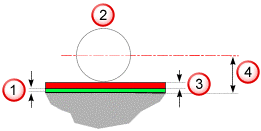

Stock allowance

Stock allowance

Wire

Wire

Spark gap

Spark gap

Compensation (Offset)

Compensation (Offset)

If the erosion of a workpiece must be made in several cuts (roughing and finishing), each cut normally uses a different compensation value or compensation register. The values for the compensation are often given in a table supplied by the machine builder or automatically entered in the compensation registers via the technology tables built into the controller.

In every case you should ensure that the appropriate linear lead-in and lead-out moves are contained within the program to enable the compensation to be switched on and off.

The output of the commands to activate and deactivate the compensation is automatically carried out by the software on the first and last moves.

On the machine

When using the Wire Compensation command, the center path of the wire is calculated and corrected directly by the nc-machine. The compensation amount is normally entered in a Compensation Register on the machine controller and activated by an appropriate command within the nc-program. The format of the command to activate the compensation and to control the compensation direction is dependent upon the nc-machine type. FeatureCAM supports the output of these commands both for single and multiple cuts (backwards/forwards cutting or Main/Sub-Programs).

The following parameters, in the Skim Pass Options dialog, control the use of wire compensation on the machine:

Total Passes

Leave Allowance

Contour Passes

Uni-Directional

Uses Macro if Available

In FeatureCAM

If the wire radius compensation is carried out by FeatureCAM the appropriate compensation value and direction is automatically used to produce a wire path that is already corrected. The path cannot be altered by changing the offset register of the nc-machine. This may be necessary, for example, when cutting a contour which contains elements or arcs which are smaller than the required compensation amount and thus cannot be cut using the machine registers.

The following parameters control the use of wire compensation: