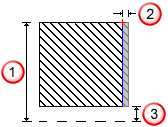

A turn Face feature is a straight cut that cleans up the front of the part.

Outer diameter

Outer diameter

Thickness

Thickness

Inner diameter

Inner diameter

FeatureCAM follows this general process:

- Determines what tool to use. The default selected tool for turning has:

- Lathe - Turning tool type.

- The proper orientation for the type of cut.

Turret

Cut direction

Orientation

Back

-Z

OR

OR

Front

-Z

OR

OR

- An 80

diamond is preferred but the default selected tool must have an included tip angle of at least 55

diamond is preferred but the default selected tool must have an included tip angle of at least 55 . You can override the tooling selection with a tool that has a narrower diamond insert, but such a tool is not automatically selected.

. You can override the tooling selection with a tool that has a narrower diamond insert, but such a tool is not automatically selected.

Note: Currently tip radius, tool length, and insert grade are not taken into account. - Picks feeds and speeds based upon the material being machined.

To view the recommended feed or speed value for a turned Face operation, select the operation in the tree view and then select the Feed/speed tab. The recommended feeds and speeds are derived from the Face column of the turning feed/speed tables.

- If roughing has been requested, generate a roughing pass possibly in multiple X steps depending upon the depth of the feature.

The roughing pass of the turn Face feature is turned off by default. Click the Strategy tab and select Rough to turn on the roughing pass.

- If the Positive Feed Direction is selected on the Dimensions tab, the roughing is performed in the +X direction.

- If the Negative direction is selected, the roughing is performed in the -X direction.

- Generates a finishing pass.

If ID is selected on the Dimensions tab, the finishing is performed in the +X direction. If OD is selected, the finishing is performed in the -X direction. The algorithm is the same as Turn and Bore feature finishing.