You can use the 5 Axis Fixture Location dialog to specify a reference point for the NC code.

To display the 5 Axis Fixture Location dialog, select 5th-axis positioning on the Indexing tab of the Stock Properties dialog, then click Fixture Location.

NC Code Reference Point — Select what to use for the reference point from:

- Pivot Point for table/table machines or Machine Zero for others

- Each setup's own fixture (each setup's origin)

- Touch-off Point

Use Origin of this Setup as the Touch-off Point — Select a setup from the list to use as the touch-off point.

Also use the setup as your part's initial orientation on the machine tool — Select this option to use the selected setup as the initial orientation of the part on the machine tool. Deselect this option to use the STOCK axis as the part's initial orientation.

Offset of Touch-point from Machine Zero — Enter the distance, in each direction, of the 5- Axis Touch-off Point from the center of the A-axis face. This distance is different for each part.

In this example, the X and Y offsets are negative and the Z offset is positive.

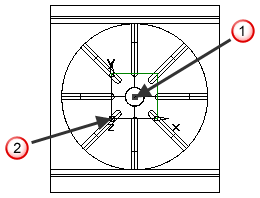

Center of A-axis face

Center of A-axis face

Touch-off Setup origin

Touch-off Setup origin

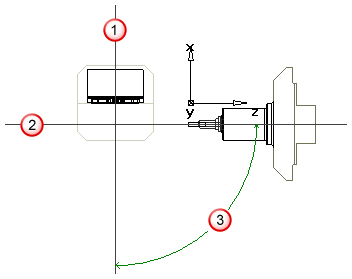

First Axis Rotational Offset — Enter the angle (measured counter-clockwise) between the spindle axis and the A axis when the B angle is set to 0.

For example, if the A-axis faces the spindle when B is set to 0, then enter 0. If it faces the door when B is set to 0, as in the example below, then enter -90. This offset is set the same for all parts machined on a specific machine.

A-axis

A-axis

Spindle axis

Spindle axis

B-axis rotation

B-axis rotation