FeatureCAM has a fully integrated Face feature performed with facing tools, and uses the facing feeds and speeds provided in the database.

|

|

|

Facing removes all of the stock down to the Z=0 plane.

Curves for a Face feature define the regions to be faced. Curves must be closed (beginning and end points are the same).

FeatureCAM typically follows this process to create a Face feature:

- Selects a face mill tool from the current tool crib using the tool diameter and cutter height as the selection criteria.

- Tool diameter is usually large for face operations as there are no tight spots or complex shapes to create.

- Cutter height is usually small for facing tools. This prevents them from being used to cut inappropriately deep features and affects how many passes it might take to face the stock.

- Using the Feed/Speed tables, calculates feeds and speeds based on the stock material being machined.

- Generates a facing pass, possibly in multiple Z steps depending upon the amount of material to remove. Face features can contain both a Rough and Finish pass.

The important aspects of a face operation are:

- Getting to depth — The tool must get to depth. This is accomplished by a plunging move.

- Vertical step — The Rough pass can have vertical steps that are controlled by the Rough pass Z increment attribute.

- Horizontal stepover is controlled in both the X and Y directions with Last pass overcut % and Lateral overcut %.

- Finish allowance — The Rough pass takes into account the Finish allowance attribute, which controls how much material to leave for the finishing pass.

- Retract removes the tool from the stock area and sets up for the next operation.

- Performs a finish pass for the final cut.

There are some variations on this process. The process can be controlled in the Stepover page of the Machining Attributes dialog, and on the Tools, Milling, Strategy, and Misc property tabs of the Feature Properties dialog. The tooling database also affects the decisions.

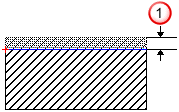

Thickness

Thickness