This setting can be used to filter out regions that have a minimal amount of rest material left by the previous tool. The default is 0 which means it tries to cut anywhere the previous tool had a double contact with the part surfaces, including a fillet of the same size as the previous tool (assuming Overcut percent is also set to 0). If Minimum rest material is set to a positive number, the remachining only includes tool paths that remove rest material that is greater than this depth. Its main use is to handle the case where you have some part fillets exactly the size of the previous tool and some that are smaller. If you do not want to remachine the part fillets that are exactly the size of the previous tool you can set Overcut percent to 0 and Minimum rest material to 1 or 2 times the machining tolerance to make sure the previous tool radius sized fillets are not remachined.

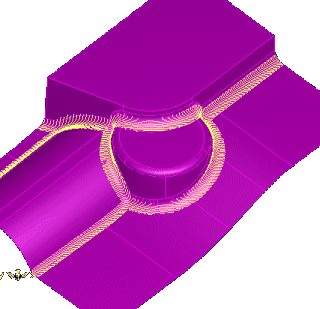

The following example part has some fillets that have a 10 mm radius and some smaller fillets. Remachining with a Previous tool diameter of 20 mm and the default Overcut percent of 5 remachines all the fillets:

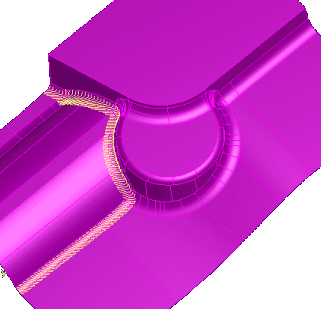

If you set Overcut percent to 0 to avoid cutting the 10 mm fillets we may get some unwanted tool paths, depending on the machining tolerance and the accuracy of the part model. Here the machining tolerance is set to 0.01 mm and we have some unwanted tool paths:

|

|

|

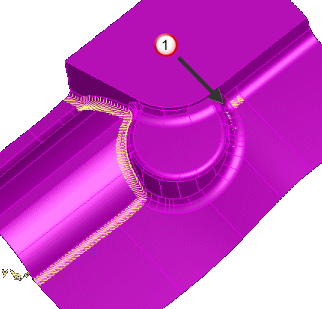

Generally, setting the Minimum rest material to twice the tolerance (0.02 mm in this case) eliminates these extra tool paths.

Another use for Minimum rest material is to eliminate noise from the remachining tool paths due to inaccuracies in the part surfaces, non-solid models, poor tolerances, and so on.

- Unwanted toolpaths

- Unwanted toolpaths