Reference existing parts and assemblies as base components that you can modify for other uses.

A derived part is a new part that references an existing part to copy bodies and other information such as sketches, work features, and parameters associatively. A derived assembly is a new part that references an existing assembly.

The source of a derived part is called the base component. You create a derived part using a part, assembly, sheet metal part, or weldment as the base component, selecting elements to include and exclude. You select elements to add, exclude, or subtract from the resulting derived component. You can also scale a derived part or create a mirror of the base part.

When deriving from a part file, the default behavior (derive style) is to maintain each solid as a solid body. If the base part contains multiple solid bodies, you can choose to import the selected bodies as a single body or as multiple bodies.

Derived parts and assemblies are useful for controlling changes to models. You can modify the original model and update all derived components to automatically incorporate changes. Derived parts can also be used to reduce memory consumption and disk space.

Derive Basics

When you derive a part, choose a derive style to determine the kind of body you want to create.

|

|

Create a single body part file from either an assembly or a multi-body part. Edges between parts or solid bodies that share a planar face are merged. This option is the default for creating a part file from an assembly. |

|

|

Merge the parts in an assembly or the selected bodies in a multi-body part into a single body in a part file. The new part retains the edges between different parts or bodies that share a planar face and retain the original appearance of those parts or bodies. This option produces the best results for a drawing view because all edges and seams are retained. |

|

|

Use this option to:

|

| Create a part file that is a single surface body. The resulting surface body retains the seams between planar faces and the original part appearances, such as bitmap threads. Use this option to create the smallest part file on disk. A surface composite part is ideal for use as an assembly substitute model state or to export in BIM Content. The resulting surface body cannot participate in the Combine operation or interference checking. The surface body can be used as a Split Tool in the Split command. | |

|

|

Creates a part file in which individual solid bodies are converted to individual surface bodies. The resulting surface bodies cannot participate in the Combine operation or interference checking. A surface body can be used as a Split Tool in the Split command. |

When you create a derived part or assembly, you choose the elements of the base component you want to include in the derived component. When creating a derived part, you can include these elements:

- Visible, exported 2D or 3D sketches that are unconsumed or shared

- Visible, exported work features

- Visible, exported surfaces

- Visible, solid bodies

- Parameters

- iMates

- Part appearance, body, feature, or face color overrides

- 2D or 3D sketches that are shared or unconsumed

- Visible, nonconstruction, work geometry

- Top-level assembly iMates

- Visible surfaces

- Parameters

- Part appearance, body, feature, or face color overrides

All features of the selected part or assembly are combined into a single feature in the browser of the derived part. By selectively including individual 2D and 3D sketches, appearances, work features, and parameters from the base part, you can define individual features from those sketches in the new part.

Uses for Derived Parts

- A casting blank can be machined several different ways.

- A standard length of tubing can be machined in different configurations.

- A weldment can be configured several ways, including post-assembly operations such as cuts and holes.

- From an assembly, groups of parts can be subtracted or joined with other parts to create a single part with the desired shape.

- From a multi-body part, you can derive one or more parts.

- In an assembly, you can use the derived parts as a layout when designing a framework for an assembly. Edit the base part and update the derived parts to incorporate changes in the layout automatically.

- From a solid, you can use a derived surface as a layout, or to define part envelopes in assemblies.

- From a solid, you can use a derived surface as a layout.

- From a part or assembly, you can derive parameters to use in a new part (you can Link Parameters from the Parameters dialog).

- From a part or assembly, you can choose to apply part appearance, body, feature, or face color overrides from source components.

- You can create two or more derived part features within a part using the same or different base parts.

- Specify some components as bounding boxes to reduce memory consumption.

- Use the Options tab to simplify the assembly, remove small or hidden parts, or patch holes.

- Use the derive style Single Composite Feature to significantly reduce the size on disk of the derived part.

Updating a Derived Part

If you change the base part or assembly, the derived part is marked for update (![]() ) in the feature browser. (For a derived assembly, this happens when associativity is enabled in the Derived Assembly dialog’s Representations tab, which is the default setting.) When you perform an update, the derived part automatically includes the associated changes from the base component.

) in the feature browser. (For a derived assembly, this happens when associativity is enabled in the Derived Assembly dialog’s Representations tab, which is the default setting.) When you perform an update, the derived part automatically includes the associated changes from the base component.

A derived part can be disassociated (unlinked) from the base part if you no longer want to update the derived part. Alternatively, you can temporarily suppress the links.

Typical Derive Operations

Inserting a component in a part file. You can use the Derive command to insert a part or assembly file on disk as new bodies in a part file. A part can be inserted as a single or multiple solid bodies (if the base part contains multiple solid bodies), or as a work surface.

Deriving a work surface instead of a solid from a part. You can use derived work surfaces to define sketch planes, work geometry, and features such as extrude to surface or split. (Derived surfaces cannot be used in a Combine operation with a solid body.) Derived surfaces can also be used to define part envelopes to aid designers in calculating space requirements between components.

To create a derived surface from a part instead of the default derived solid bodies, use the Body as Work Surface derive style.

Adding features to parts derived from assemblies Creating derived parts is a good way to do operations such as cuts across several parts in a weldment. Because a derived part is a single body, you can customize it with any part feature.

After a part is derived from an assembly, you can add features. This workflow is useful when you want to create a weldment of piece parts and want to add holes or cuts through one or more of the parts included in the derived part.

If you include one or more components as bounding boxes, a new body is created in the derived part. You can add features, move the bounding box, or change the base component and bounding box updates.

Reducing Memory and File Size

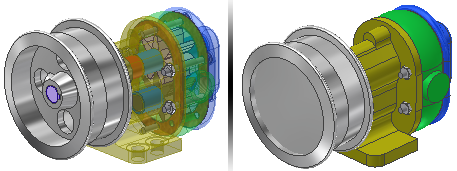

Derived parts and assemblies can reduce memory consumption and file size when used in an upper-level assembly. For example, a derived part is a single body loaded into memory, as opposed to all of the individual components in an assembly. You can use a derived part as a substitute model state in the assembly it was derived from or export it as a representation of the assembly envelope using BIM Content. The Derive command produces results similar to those of the Simplify command.

When you derive from an assembly, use less memory by enabling Reduced Memory Mode. The resulting part does not cache any source bodies; no source bodies appear in the derived part browser.

In addition, an assembly derived using the Single Composite Feature option creates a single-surface part that uses less disk space and memory and can be calculated more quickly than a derived solid. A surface body does not cache any source bodies, and cannot participate in interference checks. The surface composite body retains the base part appearance and provides better performance in consuming assemblies.

Exporting Objects and Parameters Before Deriving

As part of the normal workflow for creating a derived part or assembly, you can derive objects and parameters. (For assemblies, you can use parameters from all components in the base assembly, not just selected components.)

As an alternative workflow, you can mark objects and parameters for Export while you edit the base component (Manage tab  Author panel

Author panel  Export Objects). An arrow icon

Export Objects). An arrow icon

![]() identifies the exported objects. This is useful if the user deriving a part doesn’t have write access to the base component.

identifies the exported objects. This is useful if the user deriving a part doesn’t have write access to the base component.

You can also mark parameters for export in the base component’s Parameters dialog.

Alternative Workflow for Deriving from an Assembly

When you use the Derive command to derive an assembly, the common workflow is to create the assembly, open a new part file, and select the Derive command. From a single assembly, you can select different combinations of parts to create a single derived part with a single body or multiple bodies. Then you select bodies, work features, and so on to include or exclude in the derived part.

An alternative workflow is to use the Component Derive command in the Assembly Tools. After you select a base component for a part or assembly, this command streamlines the derive process by using default options. This command implies the base component's active design view, positional representation and model state to use in the derived assembly.

Tips for Deriving a Part from an Assembly

- Use the subtraction function

to subtract the volume of a selected part from the derived part. This enables you to create two separate parts, position them relative to each other in the assembly, and then perform a Boolean operation that results in a new single part. (You can perform a similar operation in a multi-body part file using the Combine command.)

to subtract the volume of a selected part from the derived part. This enables you to create two separate parts, position them relative to each other in the assembly, and then perform a Boolean operation that results in a new single part. (You can perform a similar operation in a multi-body part file using the Combine command.)

- Use the bounding box function

to specify a component as a bounding box if you do not need its details in the derived component. You can add features and make other modifications to a bounding box body. Changes to the base component’s size update the bounding box size.

to specify a component as a bounding box if you do not need its details in the derived component. You can add features and make other modifications to a bounding box body. Changes to the base component’s size update the bounding box size.

- Changes made to parts that are open in the active file (and that are also contained in an open assembly) automatically update when you save the change in the part and manually update the derived part.

- A derived part from an assembly is represented as one item in a bill of materials.