Prepare and run the two-stage packer that combines Scanline and Monte Carlo packing

Prepare and run the two-stage packer that combines Scanline and Monte Carlo packing

Using the packer with values matching your build project as opposed to using default values is recommended.

Determine size thresholds

The packer requires two thresholds to put the parts into three groups. To find these thresholds, Volume threshold A and Volume threshold B, you can use the packer's histogram function.

If you specify too small a center space for any part to fit into, only the scanline part of the packer runs.

- With the parts present in the build room, choose .

- Select the tab Size distribution.

- Examine the histogram and make your decision for values to use as thresholds.

Determine center space size

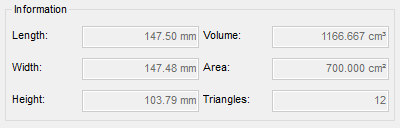

- To determine the size of the center space, a good start can be to assume a multiple of the outbox size of a part that is to be packed in the center space. To quickly check an outbox size, select a part and check the context view.

Example: The selected part is roughly 15 by 15 by 11 cm in size.

Take the values of any two sides. Depending on the size you decide to give the center space later, the part may end up rotated.

- Next, take buildroom size. It is always displayed at the bottom of the 3D display.

- Take the smaller one and subtract half the outbox multiple you decided for. This is the result, the Distance to side walls, to specify in the actual packer dialog.

Set up and run the packer

- Choose .

- Specify the values for Distance to side walls and Volume threshold A and Volume threshold B.

- Adjust the values on the tab Packer Settings as needed.

- Click Run.