Use the Feature finishing page to create a finishing or semi-finishing toolpath which clears material from the: sides, bottoms of pockets, and tops of bosses. The toolpath slices the feature at specific Z heights and then creates an offset or raster pass at each Z height.

Finish — Select the regions of the feature group to finish.

Select a region from the following:

- Walls and flats — Finishes the: sides of features, tops of bosses, and bottoms of pockets.

- Walls — Finishes only the sides of features.

- Flats — Finishes only the tops of bosses and the bottoms of pockets.

Flat style — Select the raster or offset style to use for removing material.

Select a Style from the following:

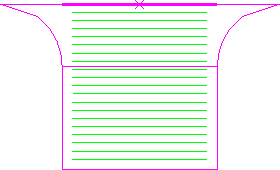

-

Raster — This comprises of parallel straight-line moves in the X - Y plane.

-

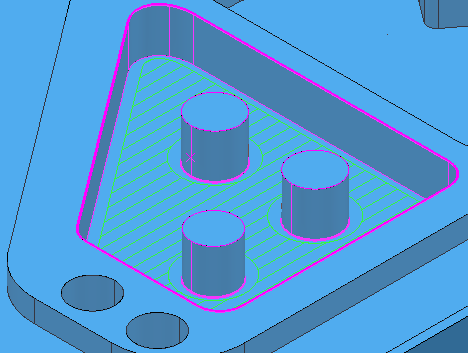

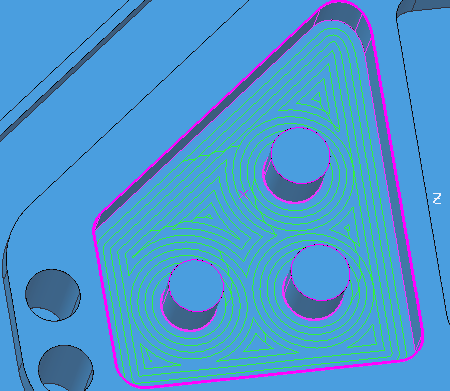

Offset model — This clears an area with contours generated by repeatedly offsetting the initial slice until no further offset is possible.

This produces a toolpath which:

- Maintains constant tool load and chip production

- Maintains cut direction

- Avoids machining small or thin-walled upstands

- Minimises full width cuts.

but increases the number of tool lifts.

-

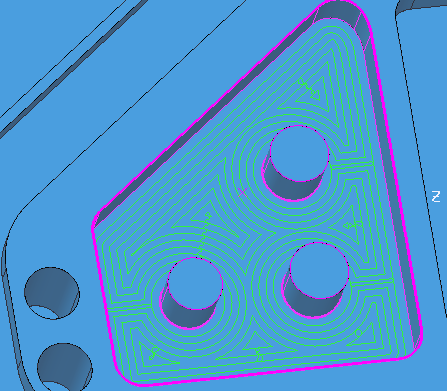

Offset all — This produces an offset toolpath which minimises the number of tool lifts and works extremely well for soft materials.

Cut direction — Select a milling style for Profile and Area.

-

Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

-

Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling. This minimises the tool lifts and tool travel.

Tolerance — Enter a value to determine how closely the toolpath follows the feature.

Thickness — Enter the amount of material to be left on the part. Click the

Thickness

button to separate the

Thickness

box in to

Radial thickness

button to separate the

Thickness

box in to

Radial thickness

Axial thickness

Axial thickness

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Rest machining — Select to change the strategy to Feature Rest Finishing and make the Rest page available with the options for rest machining. This option is not selected by default for this strategy.

Ignore chamfers — When selected the chamfers are not machined.

Ignore chamfers off.

Ignore chamfers on.

Ignore top fillets — When selected the top fillets are not machined.

Ignore top fillets off

Ignore top fillets on.