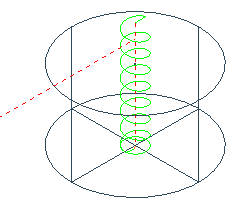

Helical milling enables you to bore out a large hole with a smaller tool. The concept is similar to trochoidal milling. The difference being that the trochoidal milling machines a slot (no variation in Z) and the helical milling drills a hole (it machines down the Z axis).

Note: For helical milling, the tool diameter should be between 60% and 90% of the hole diameter, unless the hole has been pre-drilled. If the tool is less than 50% of the hole size, an upstand will be left in the centre of the hole and the tool will break when it offsets itself inwards to finish the bottom of the hole.

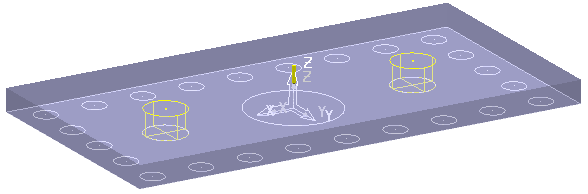

This example looks at helical milling a 18 mm diameter hole with a 15 mm diameter drill. It uses the PM_holes.dgk model in the Examples folder.

- Create a block with a Z Max of 10.

- Create a 15 mm drill tool

.

. - From the Hole Feature Sets context-menu select Create Holes.

This displays the Create Holes dialog.

On the model, select the two 18mm diameter circles and then select:

- A Create from of Circles.

- A Define top by of Top of block.

- A Define bottom by of Bottom of block.

- Click Apply and then Close the dialog. PowerMill creates the circle features on the model.

You now need to drill the holes.

- Click Home tab > Create Toolpaths panel > Toolpaths to display the Strategy Selector dialog.

- From the Drilling category select Helical and click OK. This displays the Drilling dialog.

- Click the Select button. This displays the Feature Selection dialog.

- In the Feature Selection dialog:

- In the Diameter area select 18.

- Click

.

. - Click the Select button.

- Click Close.

- On the Drilling page:

- Type a Toolpath name of Helical Drilling.

- Select a Cycle type of Helical.

- Select a Define top by of Hole top.

- Select an Operation of Drill to hole depth.

- Enter a Clearance of 5.

- Enter a Pitch of 2.

- On the Tool page, select the 15 mm tool from the list of tools. This is the tool you created in Step 2.

- Click Calculate.

- Click Close.

You can display the Helical Milling toolpath using ViewMill.

Without the tool, part way through the simulation: