This example shows you how to machine stock only and remove all segments that do not remove stock. This minimises cutting time by removing unnecessary toolpath segments. This uses the powerdrill.dgk model in the Examples file.

- Create a model area clearance toolpath and stock model as explained in steps 1 - 5 in Avoiding machining into unmachined stock.

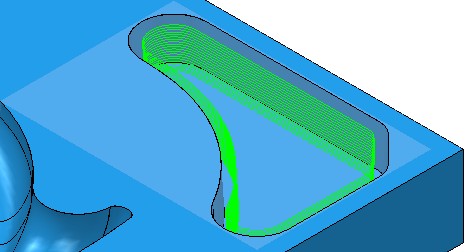

- Create a constant Z toolpath with a 20mm end mill. On the Stock Engagement page:

- Select Machine stock only.

- Enter a Detect material thicker than of 1.5.

- Enter a Minimum length removed of 5.0.

- Select the Stock model you have just created.

- Select the Stock model state of the area clearance toolpath you have just created.

- Click Calculate.

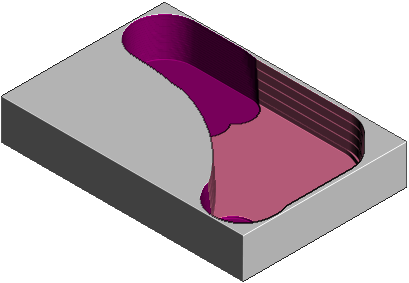

It is easier to see the toolpath without the stock model.

Looking at the ViewMill simulation:

You can see how the toolpath only machines areas where there was stock rather than the whole model.

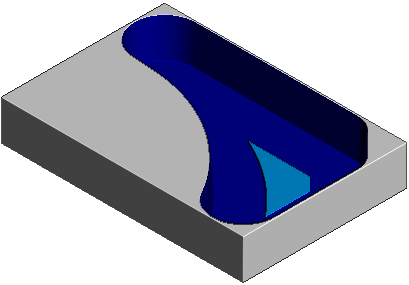

If you do not control the stock engagement, the toolpath follows the model rather than the stock.

- Create a second constant Z toolpath based on this one by clicking on

. On the Stock Engagement page:

. On the Stock Engagement page:- Select a Stock Model of none.

- Click Calculate.

Looking at the ViewMill simulation:

This toolpath machines areas that are not really necessary and therefore elongates machining times.