None — There are no leads in or out applied to the toolpath. This is the default option.

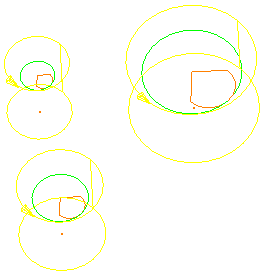

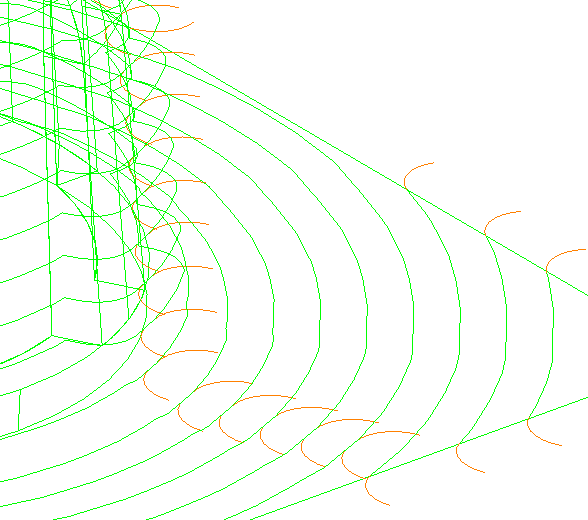

Surface normal arc — This inserts a tangential arc move at the end of each cutting path. This arc lies in the plane defined by the toolpath's tangent direction and the surface normal.

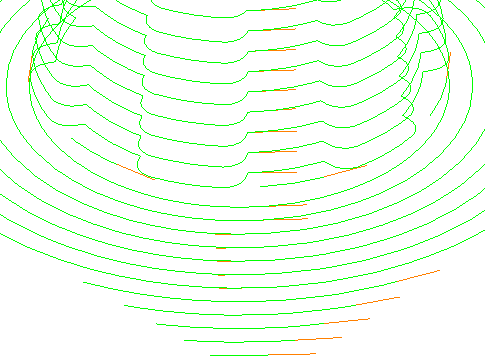

The Surface Normal Arc option offers a way of automatically obtaining the orientation that is appropriate for each segment by using the surface normal at that point. The orientation of the Surface Normal Arc varies with the steepness of the surface. On shallow regions, it approximates to a vertical arc, but on steep areas it approximates to a horizontal arc.

The Distance, Angle, and Radius fields determine the shape of the Surface Normal Arc moves.

dialog) to use this option.

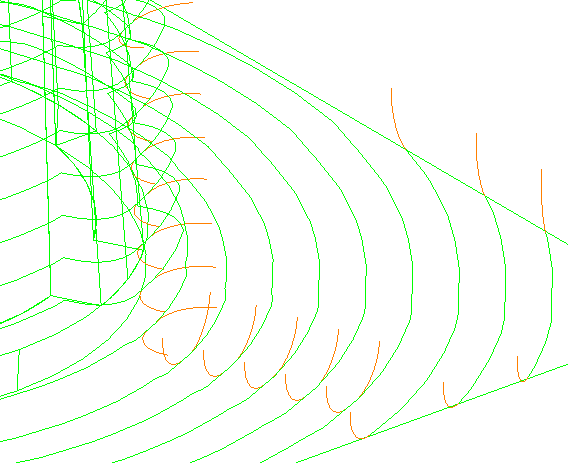

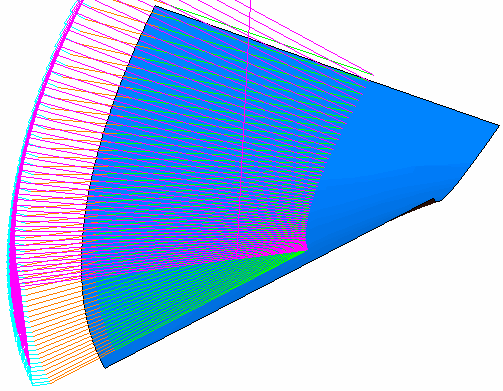

dialog) to use this option.Vertical arc — This inserts a tangential arc move at the end of each cutting path. This arc lies in a plane containing the tangent direction and the tool axis.

The Radius and Angle fields control the tangential arc produced.

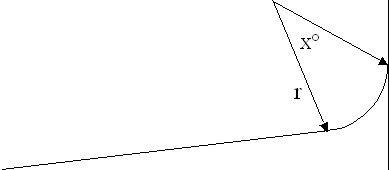

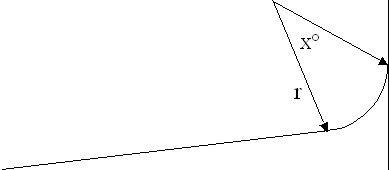

Key:

r — radius

x — tangent angle

— tangent angle

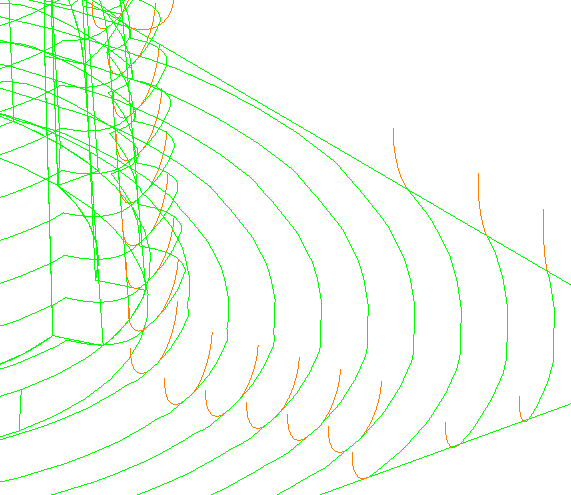

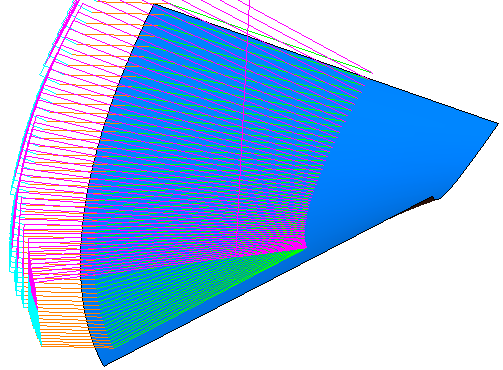

Horizontal arc — This inserts a tangential arc move at the end of each cutting path. This arc lies in the plane containing the tool axis and the tangent direction, rotated by 90 about the tangent direction.

about the tangent direction.

The Radius and Angle fields control the tangential arc produced.

Key:

r — radius

x — tangent angle

— tangent angle

Extended move — This inserts a straight tangential move at the end of each cutting move.

The Distance field determines the length of the Extended move.

Boxed — This inserts a horizontal move at the end of each cutting move.

The Distance field determines the length of the Boxed move.

Straight — This inserts a straight move at the end of each cutting move. The direction of the move is determined by the Angle.

The Distance and Angle fields determine the shape of the Straight moves.

Ramp — This ramps the tool into the model at a specified angle. This enables you to use a non-plunging tool, but is dependent on the tool and the material. Selecting this option enables the Ramp options button.

Pocket centre — This produces a tangential lead move that, in the case of a Lead In, starts at the centre of the pocket ( a Lead Out finishes at the centre). The centre is the centre of the box that encloses the closed segment. This option is useful when profiling pocket features which have been pre-drilled at the centre, although it can be used with any closed segment. This options is unavailable for lead extensions.