The Surface finishing page is similar to the Surface projection finishing page, except that there is no projection. Surface Finishing just machines the selected surface and does not attempt to machine any other surfaces.

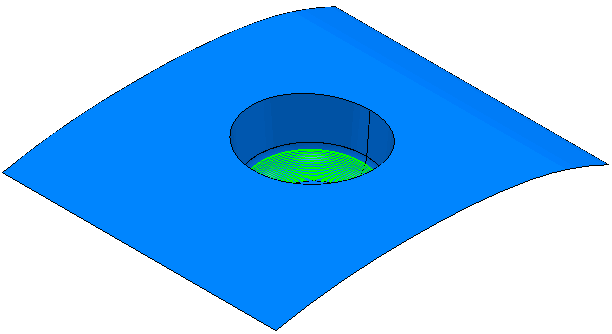

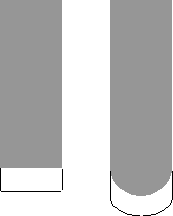

Surface side — Select whether the Outside or Inside is machined.

A Surface side of Outside

A Surface side of Inside

Surface units — Select the units used to specify the stepover and limits.

- Distance — The physical distance determines the stepover and limits. The first and last pass are on the edge of the surface. The intermediate passes are at a distance that is less than or equal to the specified Stepover.

- Parametric — The parameterisation of the surface determines the stepover and limits .

- Normalised — The surface normalised value ( in the range [0,1]) determines the stepover and limits. For example if the minimum U is 1 and the maximum U is 5 then:

|

Parametric value |

Normalised value |

|---|---|

|

1 |

0 |

|

2 |

0.25 |

|

3 |

0.5 |

|

4 |

0.75 |

|

5 |

1 |

Degouge tolerance — Enter the maximum distance, normal to the surface, that the toolpath can move to find a safe position. If gouges greater than this value are detected, then the tool is lifted axially to avoid the gouge.

Tolerance — Enter a value to determine how accurately the toolpath follows the contours of the model.

Thickness — Enter the amount of material to be left on the part. Click the

Thickness

button to separate the

Thickness

box in to

Radial thickness

button to separate the

Thickness

box in to

Radial thickness

Axial thickness

Axial thickness

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Component thickness — Click to display the

Component thickness

dialog, which enables you to specify the thicknesses of the different surfaces.

Component thickness — Click to display the

Component thickness

dialog, which enables you to specify the thicknesses of the different surfaces.

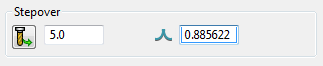

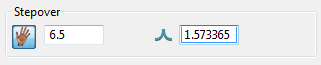

Stepover — Enter the distance between successive machining passes.

-

Copy stepover from tool — Click to load the radial depth of cut from the active tool's cutting data. The radial depth of cut is measured normal to the tool axis.

Copy stepover from tool — Click to load the radial depth of cut from the active tool's cutting data. The radial depth of cut is measured normal to the tool axis.

-

Edited — When displayed, shows value entered by you (or another user). Click

Edited — When displayed, shows value entered by you (or another user). Click

to change this value to the automatically calculated value.

to change this value to the automatically calculated value.

-

Stepover — Enter the distance between successive machining passes.

Stepover — Enter the distance between successive machining passes.

If you enter a Stepover value, then

changes to

changes to

.

.

-

Cusp height — Enter the maximum cusp height and use this value to determine the stepover.

PowerMill calculates the stepover value to give a cusp height of the machining tolerance using the current tool, when machining a plane inclined at 45

Cusp height — Enter the maximum cusp height and use this value to determine the stepover.

PowerMill calculates the stepover value to give a cusp height of the machining tolerance using the current tool, when machining a plane inclined at 45 . This is the worst case cusp height for any given tolerance.

. This is the worst case cusp height for any given tolerance.

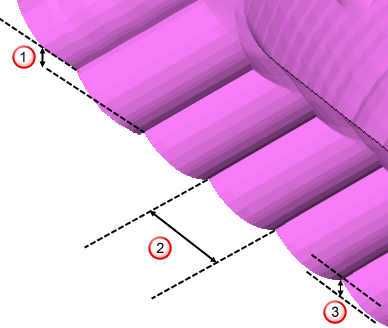

Stepdown

Stepdown

Stepover

Stepover

Cusp height

Cusp height

For more information see Linkage between stepover and cusp height.