A dovetail tool enables you to efficiently machine features, such as undercuts and gears, that would otherwise require a series of more complex toolpaths involving multiple tool changes.

Machining an undercut within an annulus

This example explains the advantages of using a dovetail tool to machine an undercut within an annulus.

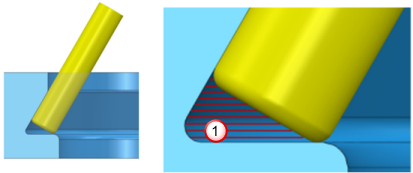

Without a dovetail tool, to machine the conical surface of the undercut requires a complex solution because a tip radiused tool, for instance, cannot access the acute angle of the corner

. After using a tipped radiused tool, you need to use a small ball-nosed tool or a tipped disc tool to sharpen the corner and remove all the material.

. After using a tipped radiused tool, you need to use a small ball-nosed tool or a tipped disc tool to sharpen the corner and remove all the material.

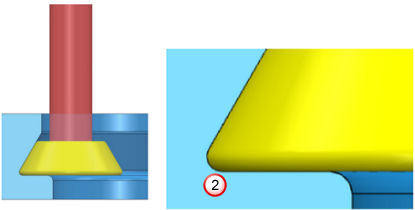

With a dovetail tool you can machine the same undercut more easily. Because the conical surface of the tool enables swarf machining, after appropriate area clearance, you can use the dovetail tool to form the undercut, fillet, and the horizontal surface of the base in one pass

. Using the dovetail tool is also beneficial because it enables you to use to larger tool and a better tool axis.

. Using the dovetail tool is also beneficial because it enables you to use to larger tool and a better tool axis.