Use the Flat machining page to specify how to machine the flat areas on a model. This page contains the following:

Machine flats — Select how to identify flat areas on the model. These options determine the location of the Z Heights.

- Off — When selected, flat areas are not considered. This option disables the rest of the dialog.

-

Area — Select to individually machine flat areas after machining a main level.

-

Level — Select to machine whole levels where a flat is detected.

Only the Multiple cuts and Flat tolerance options are available when you select Level.

Multiple cuts — Select to enable multiple vertical passes when machining flat areas.

- Number of cuts — Enter the number of passes.

- Stepdown — Enter the maximum distance between successive passes.

-

Final stepdown — Select to specify a separate stepdown distance for the final pass that is different from the normal stepdown. For example, you may want a general stepdown of 3 mm with a final pass that has a 1 mm stepdown. This gives you a couple of roughing passes followed by a finishing pass.

Note: This is different from the Z heights defined from the flat areas of the model in the Area Clearance Z Heights dialog where the flat Z heights coincide exactly with the flat surfaces. On the Flat machining page, the Z heights are offset by the Tolerance.

Allow tool outside flat — Select this option to allow the tool to go outside the flat area. This alleviates the problem of running the tool along a sharp edge.

Approach allowance (tool diameter units) — specifies the approach outside as a percentage of the tool diameter.

Flat tolerance — Specifies the distance tolerance to detect flat surfaces. Surfaces with a height which vary more than this value are not detected as flat surfaces. This enables you to include surfaces with bumps and imperfections for flat machining.

Find flats on triangles — Select to find flat areas on triangles as well as surfaces. When deselected PowerMill does not consider parts of the model containing triangles.

Ignore holes — Select to ignore holes that are smaller than the specified value.

- Threshold (tool diameter units) — Specifies which holes will be ignored. For example, with a value of 2, any holes up to twice the tool diameter will be ignored.

Approach moves

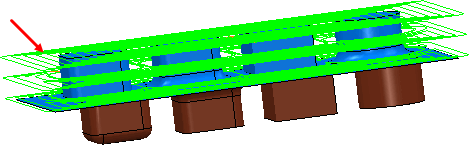

PowerMill can approach a flat area either by approaching from the outside or by ramping. Typically, it is preferable for PowerMill to approach a flat area without ramping, however it is not always possible.

To approach from outside the stock and without needing to ramp, PowerMill:

- extends a section of the flat area beyond the stock into an area already machined, and;

- fills the extended section with cutting moves.

By extending the section to an area already machined, the machine tool can approach the flat area in open space. PowerMill only extends a section of the flat area if the extended section:

- has an outside edge that the machine tool can approach.

- does not gouge the model.

- is wide enough to be profile smoothed successfully.

- can reach an area already machined within the distance of one tool diameter.

If the extended section does fails to meet the criteria, PowerMill does not extend the flat area and instead uses a ramp move to approach the toolpath.