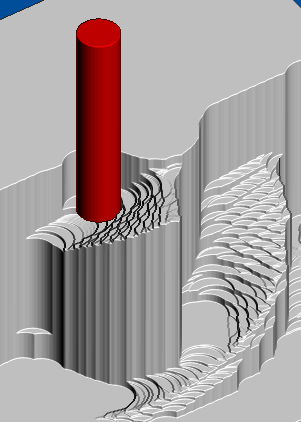

In Plunge Milling, a specialised cutting tool is used to remove large amounts of material from a component through a series of vertical plunging movements. The main advantage in using a Plunge Milling toolpath is that the material removal rates, in certain cases, exceed rates achieved by more conventional profile machining strategies.

To create a plunge milling toolpath you must have an existing toolpath which provides the pattern for the plunge milling toolpath, and a stock model which defines the current state of the stock.

Warning: Plunge machining places extreme demands on both the CNC machine and cutting tool. It is vital that you fully understand the limitations of your production facilities before undertaking any plunge machining. Failure to recognise these limitations can severely damage your equipment.

Warning: You must be careful about entry points and pre-drill holes into any pockets, otherwise they are ignored.

The page associated with the Plunge Milling strategy is:

- Plunge milling — The main page where you set the Plunge Milling strategy settings.

The remaining pages are common toolpath strategy pages.