Trochoidal moves is important when working with solid carbide tools where you are cutting on the side instead of the tip of the tools. These tools run at high speed and work best when taking deep cuts with a small stepover. This means the tool has only a small angle of engagement. As soon as the angle of engagement increases, the risk of tool damage increases. To minimise tool damage minimise the angle of engagement. You can do this in two ways:

- Avoid sharp corners.

- Avoid full-width cuts, or even cuts with a large angle of engagement which cause excessive tool loading.

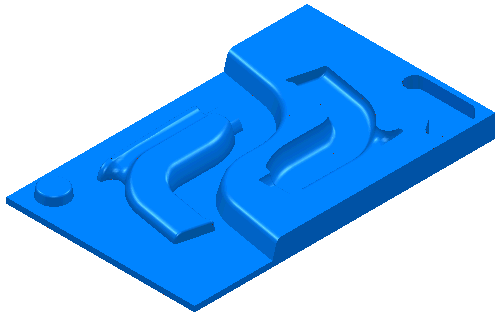

There are different mechanisms to avoid sharp corners and tool overload. Looking at the Powerdrill.dgk model from the PowerMill Examples folder:

Creating a Model Area Clearance toolpath on this model using a Style of Offset Model. On the High Speed page:

Profile smoothing — deselected

Raceline smoothing — deselected

Trochoidal moves — deselected

Links — Straight

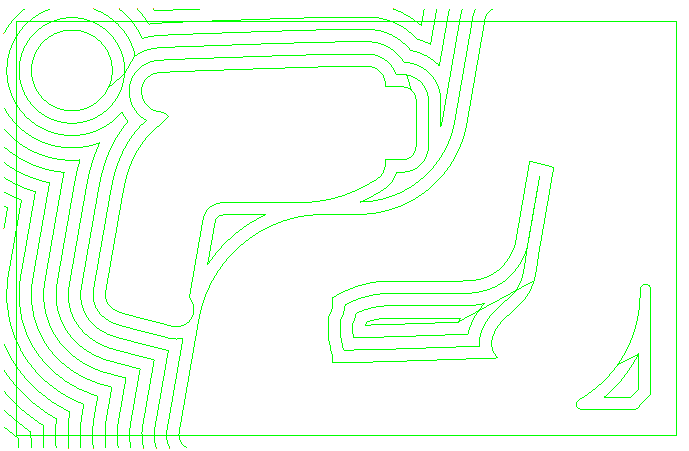

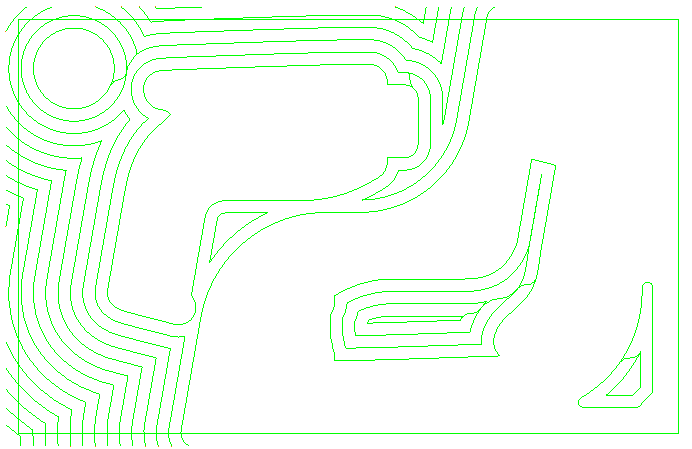

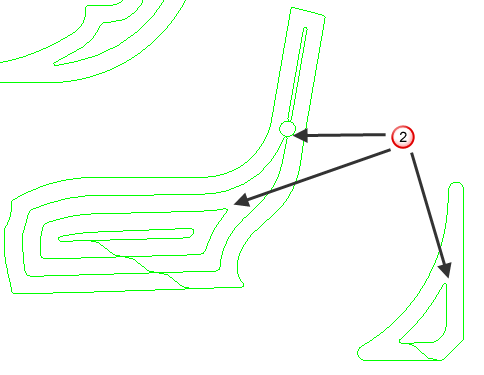

There are various problems with this toolpath, especially if you are high speed machining, when you try to avoid sudden changes in tool direction:

- The links from one offset to the next are perpendicular. This leads to a sudden change in tool direction.

— Sharp links

— Sharp links

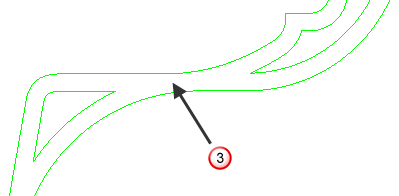

- There are too many sharp corners.

— Sharp corners

— Sharp corners

- There are too many full-width cuts.

— Full-width cuts

— Full-width cuts

Options to control all these are available on the High Speed page of the Model Area Clearance dialog.

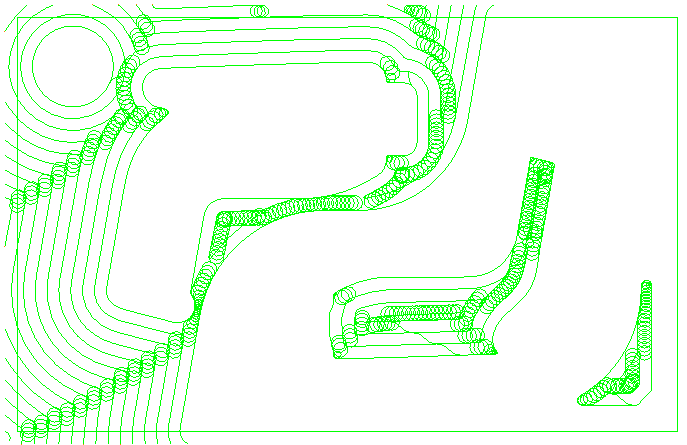

On the High Speed page:

Profile smoothing — selected

Raceline smoothing — deselected

Trochoidal moves — deselected

Links — Smooth

Looking in detail:

— Smooth links

— Smooth links

On the High Speed page:

Profile smoothing — selected

Raceline smoothing — selected

Trochoidal moves — deselected

Links — Smooth

Looking in detail:

— Smooth corners

— Smooth corners

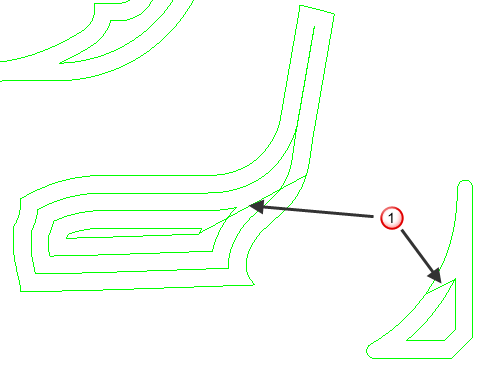

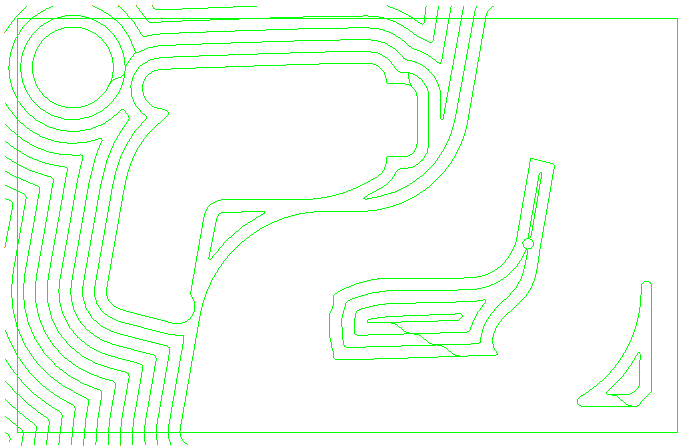

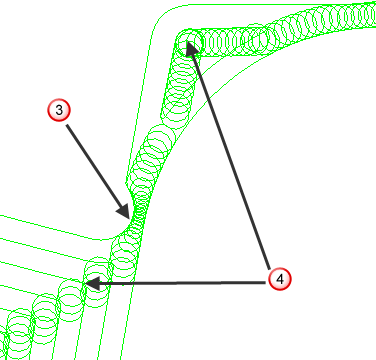

On the High Speed page:

Profile smoothing — selected

Raceline smoothing — selected

Trochoidal moves — selected

Maximum overload of 10%

Links — Smooth

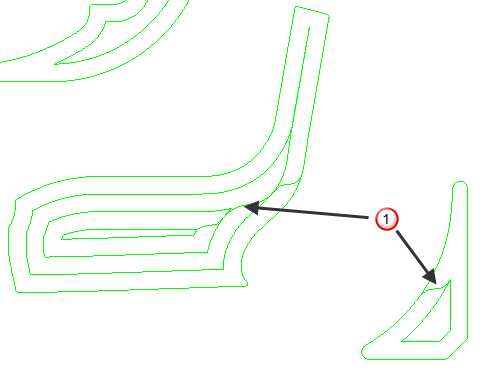

When the tool approaches overload, a trochoidal path is inserted to avoid the overload.:

— Narrow channel

— Narrow channel

— Sharp corner

— Sharp corner

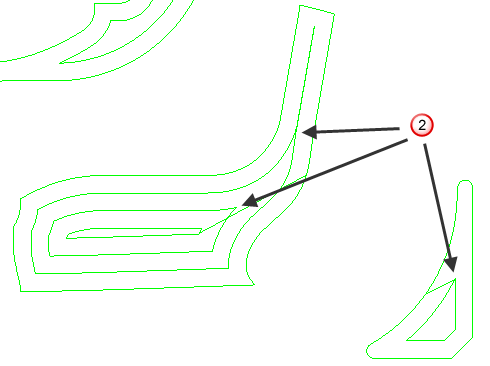

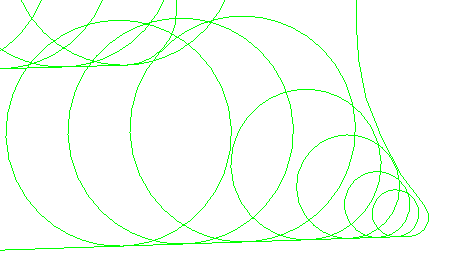

Looking in at a corner in even more detail, you can see the trochoidal path more easily:

Because some tool overload may be acceptable, it can be controlled by the slider. The default setting for the allowable overload is 10% of existing stepover. So, if you use a stepover of 10 and an allowable overload of 10%, trochoidal moves will not start appearing until an overload condition of 10% is exceeded.