A Polar orientation is where the toolpath looks like a 3-axis toolpath (the tool axis is the Z axis), however it uses rotations about the machine's singular axis rather than moving in X and Y.

Polar milling is most useful when the machine movement in X and Y is quite limited, but the machine tool is a TABLE-TABLE machine, and is free to rotate the table about Z which overcomes the limited motion in X and Y.

Rotation centre - a workplane which defines the rotation centre for the polar milling. The Z axis must be aligned with the tool axis. Only workplanes that meet this criterion are displayed. If you do not select a workplane, PowerMill uses the global coordinate system.

Lock - determines whether you lock the X or Y axis. One of them must be locked and is replaced with a rotary axis. Frequently, the X axis is locked and the rotary axis is the C axis.

Locking the X axis allows the tool to move in Y and the table to rotate.

rotation about C.

rotation about C.

linear movement in Y.

linear movement in Y.

Locking the Y axis allows the tool to move in X and the table to rotate.

rotation about C.

rotation about C.

linear movement in X.

linear movement in X.

Offset - the offset from the workplane origin selected in Rotation centre. If the X axis is locked and no offset is applied, the tool is constrained to run along X 0. If an offset of 20 is applied, then the tool is constrained to run along X 20.

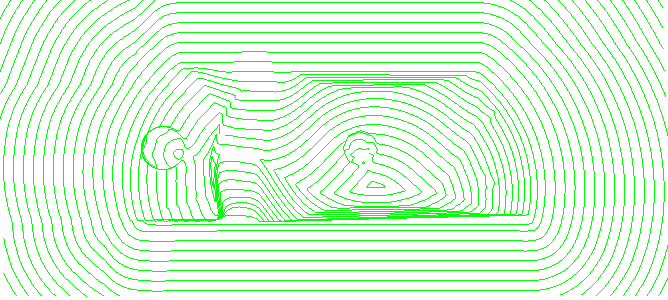

Offset of 0.

Offset of 50.

An offset gives a null area where no machining can take place because it is physically impossible for the tool to get inside this region. The null area is centred on the Rotation centre and has a diameter of the Offset. If you specify an offset, to completely machine the part, you must ensure your toolpath is not inside the null area. If the toolpath does sit inside this area, a portion of the toolpath is not created, but PowerMill applies appropriate links.

Offset of 0.

Offset of 20.

To avoid this problem, ensure the Rotation centre is at least the Offset distance away from the toolpath.

Use complementary angle — determines which of the two polar milling solutions is used.

If the tool moves in the Y axis and the table rotates about the C axis, then point  on the toolpath is machined by either rotating the table to point

on the toolpath is machined by either rotating the table to point  or

or  . If

. If  is the first solution,

is the first solution,  is the complementary solution.

is the complementary solution.

— displays the Rapid Moves page of the strategy dialog, which enables you to edit the rapid move properties.

— displays the Rapid Moves page of the strategy dialog, which enables you to edit the rapid move properties.

.

.