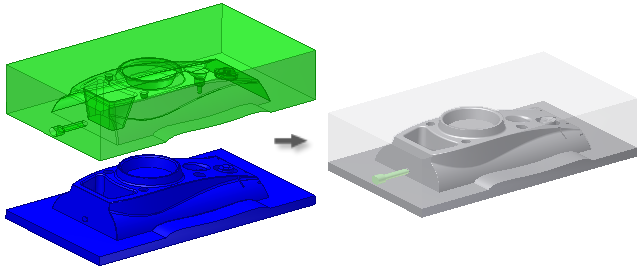

The Generate Core and Cavity feature splits the workpiece into a core and a cavity.

The core and cavity do not generate successfully when unpatched holes exist in the plastic part, or when runoff surfaces on the parting line do not generate. You can use this feature to separate the workpiece only after you create a valid patching surface, runoff surface, and workpiece. Set a Repair Tolerance value to close gaps.

Use Preview/Diagnose to evaluate the parting surface and visualize body separation and opacity. Click the Parting Diagnostics tab to evaluate the model for problems.

What if there are errors?

If the errors are small gaps, set the Repair Tolerance value to close the gaps.

If the errors are too significant to repair by changing a tolerance value, generate the sick core cavity to retain a record of the flaws. Use Inventor modeling commands to repair the gaps or other flaws in the model.

When you finish manually repairing the model, return to the Mold Design browser, right-click the Core Cavity feature and then click Edit Feature. On the dialog box, click Preview/Diagnose to check for errors. Repeat these steps until the core cavity is resolved successfully.