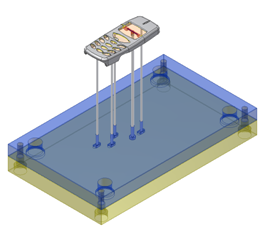

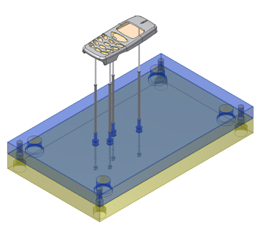

An ejector is a pin or sleeve that pushes a plastic part out of a mold. The Ejector feature creates an ejector pin or ejector sleeve.

Ejector Sleeve with Center Pin

Ejector pins and ejector sleeves

An ejector pin is a steel pin located on the B-side of the mold. When the ejection system is activated, the pin pushes the plastic part or runner system out of the mold. An ejector sleeve is a hollow cylinder that surrounds a fixed center pin. When the ejection system is activates, the sleeve slides over the center pin. It pushes the plastic part off the center pin and out of the mold. An ejector sleeve commonly helps eject features of the part, such as hollow bosses.

Anti-rotation

Ejector pins do not always have a round cross section throughout the entire length of the pin. In many cases, the tip of the pin is shaped to fit exactly into a mirror-image contoured recess in the plastic part (a hollow boss). Therefore, it is crucial that the ejector does not rotate, as it would no longer match correctly with the shaped recess in the part. Anti-rotation systems prevent the ejectors from rotating. You can choose from four different types of anti-rotation system. Two types work by machining the shoulder of the ejector pin to prevent rotation. The other two work in combination with a stop pin to prevent the ejector from rotating.

Clearance

Components like ejectors move back and forth within the mold base or core. A small amount of space called a pocket or running clearance is allowed for this movement. The Clearance tab is used to set the size of the pocket in the mold base so that it corresponds to the requirements of individual ejectors. Set the clearance so that the ejector does not catch on the mold base or core.

Trim ejectors

The ejectors must be long enough to eject the plastic part or runner from the mold. If the supplied ejector is longer than required, it can be trimmed to match the plastic part or runner more closely.