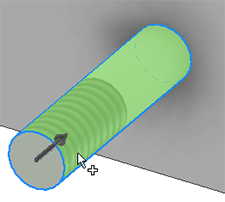

Create threads on one or more contiguous cylindrical or conical faces.

What's New: 2020

Typically, use this command to create external features. Use the hole command for creating threaded holes.

- On the ribbon

:

:

- Part file: 3D Model tab

Modify panel

Modify panel  Thread.

Thread.

- Assembly: 3D Model tab

Modify Assembly panel

Modify Assembly panel  Thread

Thread

- Weldment assembly: Weld tab

Preparation and Machining panel

Preparation and Machining panel  Thread

Thread

- Part file: 3D Model tab

- If desired, specify a preset.

Note: To set preference for preset behavior for threads, click the gear icon.

- In the graphics window, select one or more faces for the thread locations. To create multiple faces, each face must be the same size, diameter, and contiguous to one another.

Tip: For non-full face threads, select the face near the edge where the thread starts.

- Click a drop-down arrow next to the following settings to set the thread type using predefined types from the Thread data spreadsheet:

- Type: Specify a thread type from the list defined in the spreadsheet.

- Size: Specify a nominal size (diameter) for the chosen Thread Type.

- Designation: Specify a pitch.

- Class: Specify a thread class for the chosen Size and Designation.

- Direction: Specify the direction of the thread. This is used for thread notes, and does not affect size or thread appearance.

- Set the thread depth:

- Enter thread depth of the selected face. Specify Offset as needed.

- Depth: (Default) Threads the entire length of the selected face, defining the offset, length, and direction automatically.

- Offset: If Depth is set to Off, specify the distance from the start face of the thread.

- Enter thread depth of the selected face. Specify Offset as needed.

- To create a new thread, click the plus sign

.

.

- (Optional) Under Advanced Properties, if desired, clear the Display thread in model check box to hide thread graphics when the thread is created.

- Click OK.

To ensure performance is maximized, Inventor displays the threads using a cosmetic appearance, or texture, rather than modeling actual threads.