You can use family mold functionality to create a mold design for multiple plastic parts in one mold base.

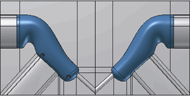

A family mold is a multi-cavity injection mold in which each cavity forms a component part of the finished product. You can create an individual core and cavity, and individual inserts, for each plastic part.

The key to creating a successful family mold is balance. The plastic parts must be similar in shape, volume, and flow length.

Use Moldflow Insight or Adviser analysis tools help solve balance problems and achieve accurate dimensions, faster cycles, less scrap, greater efficiencies, and lower production costs.

Place and remove multiple plastic parts

The methods available to place multiple plastic parts are:

- Add parts one at a time, using the Plastic Part command.

- Select a multi-body part file and add the required plastic parts.

- Use an existing core and cavity that contains a mold design for multiple parts.

When you place plastic parts, or a core and cavity, plastic part nodes display in the Mold Design browser.

You can delete plastic parts in the Mold Design browser. If you delete all the plastic parts, all Mold Design components are deleted.

Adjust positions of plastic parts

Use the Adjust Position command with one of the following methods to specify the positions of parts:

- Align the parting planes of two plastic parts.

- Align the centers of two plastic parts.

- Adjust the relative position of two parts by changing the x, y, and z offset values.

Activate plastic part for core and cavity design

The methods to activate a plastic part are:

- In the Mold Layout tab, click Core/Cavity.

- In the Mold Design browser, right-click a plastic part node, and then click Edit Core/Cavity.

- In the Mold Design browser, double-click a plastic part node.

To exit the core and cavity design environment, click Finish Core/Cavity in the Core/Cavity tab.

Mold Design commands for plastic parts

Mold Design commands are arranged on three tabs:

- Mold Layout

- Core/Cavity

- Mold Assembly

The Mold Layout and Mold Assembly tabs contain commands you use to create designs in the Mold Design environment.

The following commands work only for a single part:

- Adjust Position

- Adjust Orientation

- Ejector

- Slider

- Lifter

- Pattern

There is a Plastic Part selection button in the dialog boxes for each of these commands.

- To create a plastic part family mold Uses two plastic parts to create a family mold.