Bi-injection molding process overview

A bi-injection molding process involves injection of two different materials into a mold at separate injection locations, which are controlled independently by two different injection units.

Bi-injection processes have two barrels and two nozzles in an injection molding machine.

Note: It is possible to have more than one gate (cavity entrance) location fed by each nozzle, to control the distribution of the two materials throughout the part cavity.

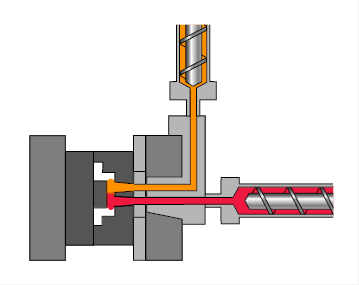

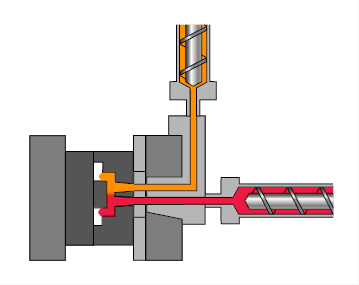

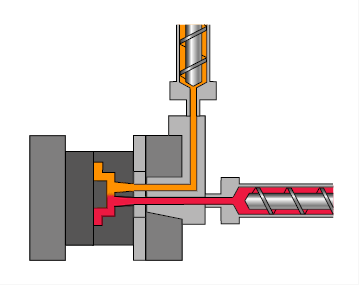

Figure 1: Bi-injection molding process

Material A and Material B are injected through separate nozzles. A weld (or meld) line forms where the two materials meet.