You can create holes in solids by specifying their use from a range of industry-standard hole types and sizes. Creating holes in this way also marks them as a solid feature; an operation applied to a solid, the details of which are stored and kept as a history in the solid feature tree. This is useful as solid features can be redefined, reordered, suppressed and deleted using the solid feature tree. You can also add chamfers to solid hole features, and mark the holes for machining in PowerMill.

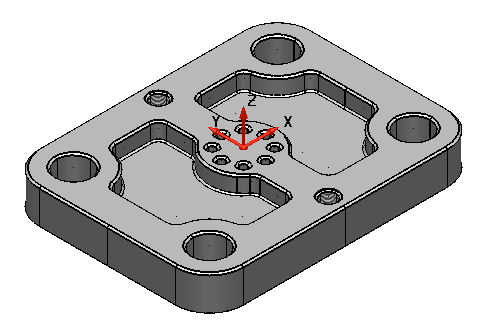

To add solid hole features, with chamfered edges, to the plate:

- Click Solid tab > Feature panel > Hole.

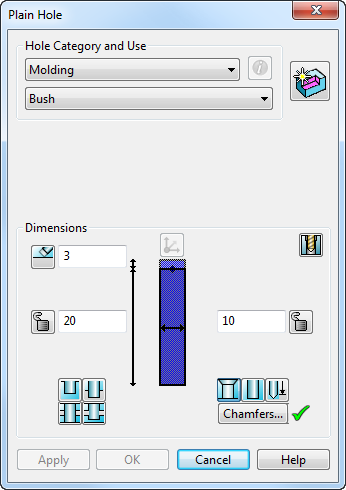

The Hole dialog is displayed:

- Click in the Command Input box on the Status Bar and type:

0 2.5 0

- Press the Enter key.

- Select General Machining (ISO) from the Hole category drop-down list.

- Select Tapped from the Use drop-down list.

- Select Unified National Course from the Standard drop-down list.

- Select 1/2 inch from the Size drop-down list.

- Enter 0.5 in Set tapping depth.

- Click

Chamfers.

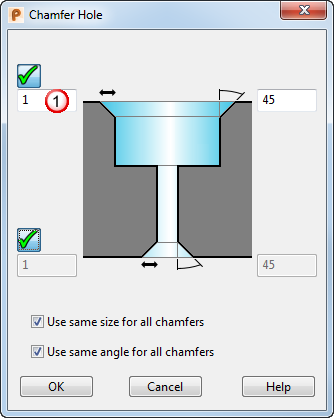

The Chamfer Hole dialog is displayed:

- Enter

0.05 to

Set the hole base chamfer size

.

.

- Click OK.

- Click

Apply.

- To add a second, symmetrical hole, click in the Command Input box in the Status Bar and type:

0 -2.5 0

- Press Enter.

- Click OK.

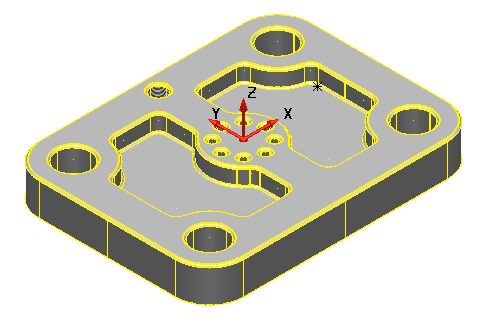

- Click in an empty space in the graphics window to deselect the model.

Your model should look like the one shown below: