Hydraulic Turbines

A turbine is a rotating machine that extracts energy from a fluid in motion, and converts it into mechanical energy.

Objectives

Most turbine applications focus on determining the following:

- Flow behavior (presence of upstream and downstream eddies)

- If a flow straightener is needed upstream or downstream of the device.

- Resultant torque

- Resultant rotational speed

- Power

- Efficiency

- Slip as a function of load (rotating speed at load vs. no-load rotating speed)

Application Examples

Typical examples of hydraulic, Frances, and Impulse turbines include:

- Turbine flow meter

- Water wheel

- Dentist drill

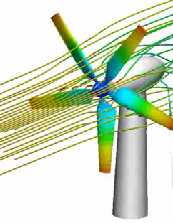

- Windmill

Modeling Strategy

Error-free CAD geometry without extraneous features is essential to analysis efficiency. Remove small edges and sliver surfaces, particularly on the impeller and volute casing. Close small gaps around wear rings and packing.

Extend the suction (inlet) and discharge (outlet) at least 3-4 hydraulic diameters from the impeller. This is necessary to prevent the boundary conditions from directly influencing the results.

The rotating region should just envelop the impeller, but not touch any static parts.It should extend halfway between the outer diameter of the impeller and the cutwater. Click here for more rotating region guidelines...

To facilitate local mesh refinement around blade leading edges and the volute tongue of a pump housing, try to construct them using distinct surfaces (instead of large surfaces that extend over a the expanse of the blade or volute). This makes it much easier to apply local mesh refinement to these critical regions.

Analysis Set up

There are two primary methods for running turbine applications:

Method 1: Applied Load. Use this method to determine the rotational speed for a known load.

- Use velocity polygons to calculate the ideal rotational speed.

- Using a non-impulsive startup, run until this specified rotational speed is reached.

- Change the method to Free Spinning, and assign a load. Run additional time steps until the actual rotational speed is achieved.

Method 2: Prescribed Speed. Use this method to determine the relationship between rotational speed and load.

- Using a non-impulsive startup, run until the first rotational speed is reached.

- Determine the resultant torque for this speed.

- Adjust the rotational speed to the next value, and continue the analysis. Record the resultant torque for this rotational speed. Repeat for additional rotational speeds.

Materials

Create and assign a rotating region material to the volume surrounding the impeller. On the Material Editor, set the Scenario type to Known Rotational Speed. Specify the rotational speed using a table, and increase from 0 to the full speed over 50 time steps.

Example:

- If a five bladed turbine rotates at 3000 RPM, the blade-pass time step size is the time required to rotate 72 degrees (360 / 5 = 72).

- At 3000 RPM, this works out to a time step of 0.004 seconds. (D / N x 6 = 72 / (3000)x(6) = 0.004)

- The time needed to achieve full rotational speed over 50 time steps is 0.2 seconds. (50 x 0.004 = 0.2 seconds.) The values of the rotational speed table are:

| Impeller Speed(RPM) | Time, sec |

| 0 | 0 |

| 3000 | 0.2 |

| 3000 | 100 |

Boundary Conditions

- Inlet: Specify a velocity or flow rate boundary condition.

- Outlet: Specify Pressure = 0.

Mesh

- Unless heat transfer is relevant, suppress solid parts such as the impeller, volute casing, and wear rings.

- Define the mesh distribution using either Automatic-Sizing or Manual Sizing.

- Automatic sizing creates a distribution based on the curvature of the geometry. It strives to blend mesh gradients across the entire model. Use the Use uniform setting on the rotation region. This prevents artificial gradients in the flow due to mesh size variations

- Alternatively, use manual mesh sizing. The typical strategy is to assign element sizes to parts based on their size, and to refine using surface and edge sizing.

- The following considerations apply for both mesh strategies:

- A fine enough mesh density is critical to a successful analysis. Because of the high flow gradients in a rotating device, it is essential that the mesh be fine enough to resolve them.

- Refine the mesh locally on vane leading edges and volute tongues to ensure the curvature is adequately represented. These are typically critical areas and are where large pressure and flow gradients occur.

- Check the mesh distribution on the suction side of each passage. An adverse pressure gradient often occurs in this region, and it is essential that enough mesh exist to adequately resolve the flow gradients.

- Ensure that nodal aspect ratios within the rotation region are below 100. To check aspect ratio, enable Stream Function in the Result quantities dialog, and run 0 iterations. Create an iso surface to visualize Nodal Aspect Ratio.

Monitor Points

Create a monitor point at the center of the outlet to monitor pressure and flow rate (multiply the velocity by the outlet area).

To do this:

- Right click off the model, and click Monitor points from the menu.

- Position the point, and click Add.

Running

For both methods (Applied Load and Prescribed Speed), a steady-state rotational speed must be achieved. The best way to do this is to use a non-impulsive startup.

Step 1: Non-Impulsive Startup--Time Step Size and Number of Time Steps to Run

Because of the rotational speed and boundary condition ramp-up, it is important to run enough time steps to properly start the flow and then to run it out a sufficient number of revolutions to achieve fully-developed flow. A good guideline is to run the analysis in three phases:

Phase 1: Ramp up the rotational speed and boundary conditions.

Phase 2: Run 20 complete revolutions to achieve fully-developed flow using a time step equal to a single blade pass interval.

Phase 3: Run 1 revolution using a time step equal to the passage of 3 degrees. This final revolution ensures that the flow, pressure, and hydraulic torque have reached steady-state.

Some planning and simple calculations are required to determine the correct time step sizes and the number of time steps to run for each phase. An easy way to illustrate this is through an example:

Example

A five-bladed impeller rotates at 3000 RPM. The blade-to-blade time step size is 0.004**seconds**. t = D / N x 6. (D = 360 / number of blades; N = RPM); t = 72 / (3000)x(6) = 0.004s

Phase 1:

- The rotational speed requires 50 time steps to ramp up. This is 0.004 x 50 = 0.2 seconds.

- The outlet boundary condition requires an additional 50 steps. This is 0.004 x 50 = 0.2 seconds.

A total of 0.4 seconds and 100 time steps have elapsed.

Phase 2:

- At full speed, 20 complete revolutions requires an additional 100 steps. (at 1 time step per passage, it takes 5 steps per revolution, resulting in 100 steps to rotate 20 revolutions). This is another 0.4 seconds.

An additional 0.4 seconds and 100 additional time steps have elapsed.

Phase 3:

The time step to rotate 3 degrees per time step is 0.000167 s. (t = 3 / N x 6 = 3 / (3000) x (6) = 0.000167seconds)

- At 3 degrees per time step, 120 steps are required for one revolution

For phase 3, an additional 0.02 seconds and 120 steps have elapsed.

To summarize:

| Time Step Size | Number of time steps | |

| Phase 1 | 0.004 s | 100 |

| Phase 2 | 0.004 s | 100 |

| Phase 3 | 0.000167 s | 120 |

After the rotational speed has been reached, modify the rotating region to be free spinning, and assign an inertia to act as a resistive load. To do this:

- Return to the Materials task, and edit the rotating region material.

- Change the Scenario Type to Free Spinning.

- Specify the load as the Inertia.

- Run additional time steps until a steady-state rotational speed is once again achieved.

Step 2: Prescribed Speed Method

- After the rotational speed has been reached, determine the resultant torque by clicking Review_Rotating region results.

- Increment the rotating speed, and repeat phases 2 and 3, described above. This is necessary to ensure that steady state solutions have been reached for the flow, pressure, and torque.

Results Extraction

To view the time history of hydraulic torque, click Results (tab) > Review (expanding panel) > Rotating Region Results. This data is also saved to an external "csv" file in the folder containing the scenario, and can be graphed by importing into Excel.

Track the solution progress using the Monitor Point created at the outlet. This provides a focused view of the solution progress at a critical area.

To animate graphical results:

- Set the time step to half of a blade pass.

- Set the Save Interval (on the Solve dialog) to 1.

- Continue the analysis, and run enough time steps to complete a complete revolution.

The desired results quantities from most turbine applications include:

- Rotational speed: Read from the rotation region results table (Review_Rotating region results)

- Torque: Read from the rotation region results table (Review_Rotating region results)

- Power: Compute as the product of rotational speed and torque.

- Efficiency: Compute as the Power / (flow rate x pressure drop)

Things to avoid

Avoid not defining an adequate mesh. Rotating analyses are typically more sensitive to mesh distribution than static analyses. Make sure high gradient areas such as blade leading edges, the volute tongue, and the suction side of the blade passage are adequately meshed.

Avoid the impulsive start-up. This is when the full rotational speed is specified from the beginning of the analysis. It is a condition to be avoided because it is not physically real, and can lead to separation regions in the blade passages. Alternatively, gradually increase the rotational speed of the rotating region using a table definition as described above.