Woven General Tab

Specify the strengths of your woven lamina.

Fields I, K, and L must be specified on the General tab, while field J is optional (see image on previous page):

I - Ultimate Lamina Strengths (required)

Three ultimate strengths are required to characterize a woven composite.

- +S11: Ultimate tensile lamina strength in the fill tow direction (x-direction).

- -S11: Ultimate compressive lamina strength in the fill tow direction (x-direction).

- S12: Ultimate in-plane shear strength of the lamina.

J - Weave Knee Strengths (optional)

The weave knee strengths correspond to the stresses at which matrix failures occur in a tow. If the knee strengths are unknown, they will be automatically calculated based upon the ultimate strengths and the material system specified. For additional information regarding knee strengths, please refer to Appendix D.

- Tensile Knee Strength: Corresponds to the applied tensile stress in the fill tow direction (x-direction) at which matrix failure occurs in the warp tow.

- Compressive Knee Strength: Corresponds to the applied compressive stress in the fill tow direction (x-direction) at which matrix failure occurs in the warp tow.

- In-Plane Shear Knee Strength: Corresponds to the applied in-plane shear stress at which matrix failure occurs. For a balanced weave, the shear knee strength will cause matrix failure in the warp and fill tows simultaneously.

K - Weave Geometry (required)

Some of these values may not be available from standard manufacturing data sheets. Refer to Appendix E for guidance.

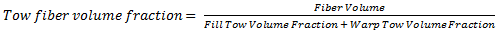

Tow fiber volume fraction (calculated):

Fill Tow Volume Fraction (required): This is the volume fraction of the fill tows within the lamina.

Warp Tow Volume Fraction (required): This is the volume fraction of the warp tows within the lamina.

Harness (required): This parameter specifies the type of weave. A value of one, corresponds to a plain weave, four corresponds to a 4-harness satin, five corresponds to a 5-harness satin, and eight corresponds to an 8-harness satin.

For a balanced weave, the Fill and Warp Volume Fractions must be within the ranges given below:

Full Unit Cell

- Plain - 0.20 ≤ BVF ≤ 0.377

- 4-Harness - 0.24 ≤ BVF ≤ 0.40

- 5-Harness - 0.28 ≤ BVF ≤ 0.42

- 8-Harness - 0.25 ≤ BVF ≤ 0.41

Reduced Unit Cell

- Plain - 0.20 ≤ BVF ≤ 0.377

- 4-Harness - 0.24 ≤ BVF ≤ 0.4

- 5-Harness - 0.28 ≤ BVF ≤ 0.4

- 8-Harness - 0.25 ≤ BVF ≤ 0.4

For an unbalanced plain weave, the sum of the Fill and Warp Volume Fractions must be less than 0.68 (Note: 4, 5, and 8-harness satin weaves must be balanced.

L - Weave Degradation (required)

These parameters are constants used to degrade the fiber and matrix after a failure is predicted in Helius PFA. When a matrix failure event is predicted, the elastic constants of the matrix are degraded by the parameter specified for Matrix Degradation. When a fiber failure event is predicted, the fiber elastic constants are degraded by the parameter specified for the Fiber Degradation and the matrix elastic constants are degraded by the value specified for the Matrix Degradation. These parameters may be overridden when performing an analysis with Helius PFA and are used by Composite Material Manager to predict the properties of the composite after a failure event to reduce overhead in the analysis. The recommended value for matrix degradation is 0.1, and the recommended value for fiber degradation is 0.01. For more information on degradation parameters and their significance to Helius PFA, please refer to the Theory Manual and the Helius PFA User's Guide.