Display the results

In this task you will examine several ways to display results.

In this task, you will:

- Determine the results of an analysis at a specific point on the mold.

- Learn how to access the result properties, and update them to create a different output.

If you have the model from the previous task open, skip the next three steps.

Double-click

Open Project from the tasks pane, and navigate to the Postprocessing.

Open Project from the tasks pane, and navigate to the Postprocessing.Open the Postprocessing project you created in the first task of this tutorial.

Double-click cpu_base in the Project View pane to open the model.

In the Layers panel, right-click New Triangles and select Hide All Other Layers.

Select Fill time in the Study Tasks pane.

Click

(Results tab > Animation panel > Play) to animate the result.

(Results tab > Animation panel > Play) to animate the result.Click

(Results tab > Animation panel > Step Forward) several times. Each frame represents a different time in the cycle.

(Results tab > Animation panel > Step Forward) several times. Each frame represents a different time in the cycle.The time the frame represents within the cycle is shown to the right of the slider bar in the Animation toolbar. It is also shown beneath the result type description in the top-left corner of the Model pane. You can drag the slider bar to the left or right to select a time in the analysis that is of interest.

Drag the slider bar along until the time elapsed is about 1.5 seconds.

Click

(Results tab > Properties panel > Plot Properties). The Plot properties dialog appears. This allows you to edit the way the results are displayed.Tip: You can also right-click the result name in the Study Tasks pane and select Properties, to access the Plot properties dialog.

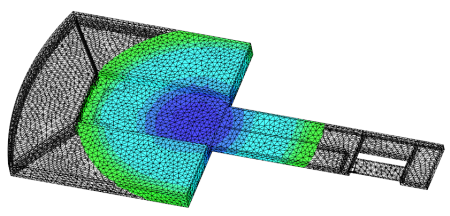

(Results tab > Properties panel > Plot Properties). The Plot properties dialog appears. This allows you to edit the way the results are displayed.Tip: You can also right-click the result name in the Study Tasks pane and select Properties, to access the Plot properties dialog.Select the Mesh Display tab.

From the Edge display on undeformed part box, select Element lines.

From the Surface display box, select Transparent and leave the Opacity at the default value 0.1.

Select the Optional Settings tab from the top of the dialog box and change the Color option to Banded.

Click OK to view the result.

Click

Play.

Play.Drag the slider bar along until the time elapsed is again about 1.5 seconds.

Click

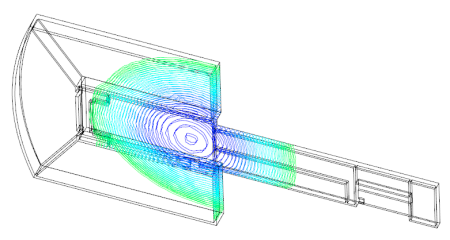

Plot Properties and select the Methods tab.

Plot Properties and select the Methods tab.In the Selection box, click Contour and change the Number of contours to 50.

From the Mesh Display tab, select Feature lines from the Edge display on undeformed part box and increase the transparent opacity to 0.5 in the Surface display.

Click OK.

Click

Play to view the result.

Play to view the result.You will now look at how a result varies over the cycle time and, specifically, what the bulk temperature distribution is at the end of the cycle. Select Bulk temperature from the Results section of the Study Tasks pane.

Click

Plot Properties.

Plot Properties.From the Mesh Display tab, select the Feature lines option.

From the Optional Settings tab, ensure the Color is Banded.

Click OK and then click

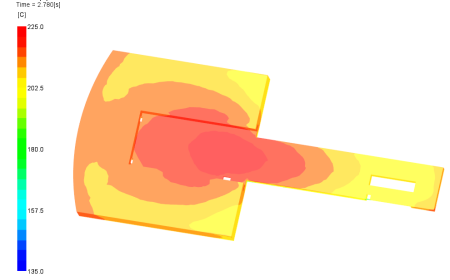

Play to view the result.

Play to view the result.From the scale bar on the right of the Model pane, it appears that the highest temperature is about 225°C. The temperature at a specific point can be determined using the

Examine feature.

Examine feature.Select

(Results tab > Examine panel > Examine), then click the part of the model you are interested in. The temperature at the point selected is displayed.

(Results tab > Examine panel > Examine), then click the part of the model you are interested in. The temperature at the point selected is displayed.Click

Plot Properties.

Plot Properties.Select the Animation tab and from the Animate result over box, select Single dataset from the drop-down box. This allows us to select a single time within the cycle that we are interested in. From the Animate result at box, select the a time at approximately 2.8 seconds.

From the Scaling tab, enter 135 in Min and 225 in the Max text boxes.

Click OK.

The appearance of the model has changed. This is because the scale on the right of the screen has been automatically modified to represent the temperature range within this frame. Previously it accommodated the temperature range throughout the cycle.

Click

Step Backward several times.

Step Backward several times.Each step in the animation now represents a decrease in the temperature displayed. The description beside the slider bar now reads C (for Celsius). Previously it displayed s (for seconds).

The description at the top of the Model pane shows:

The result being represented (Bulk temperature)

The maximum value represented graphically by the current frame (anything above this value is in gray)

The time in the cycle that this profile represents (about 2.8 seconds).

If you are interested in a specific value, you can use this value as a limit in the display. You will now find what portion of the model is above 160°C at about 2.8 seconds of the cycle.

Click

Plot Properties and select the Scaling tab.

Plot Properties and select the Scaling tab.Select the Specified option and enter 160 in the Min box and 225 in the Max box. Click OK.

Again the coloring of the model has altered to reflect the changed scale bar limits, and the gray area represents sections of the mold outside the colored temperature range shown at the specified time. Rotate the part to view rib section on the underside of the part.

Click

and step through the temperature profile of the part.

and step through the temperature profile of the part.Weld lines can affect the performance of a part. It is important that the temperature of the flow fronts at the time the weld line is formed is within the processing parameters of the material. A temperature that is too cool will result in an area of weakness. How can we investigate this?

Select Weld lines from the Results section of the Study Tasks pane.

The scale bar represents the angle of the weld line. We are interested in the flow front temperature at that point.

Click

Plot Properties. Select the Highlight tab.

Plot Properties. Select the Highlight tab.From within the Color box, click the

Browse button and select Temperature at flow front from the Select Result dialog that appears.

Browse button and select Temperature at flow front from the Select Result dialog that appears.Click OK twice.

We can see from the scale bar that the temperature of the flow fronts are in the range of about 215–220°C when the weld lines were formed. We need to compare this result with the material processing properties.

Right-click

(Select Material) in the Study Tasks pane, and choose Details from the menu.

(Select Material) in the Study Tasks pane, and choose Details from the menu.From the Recommended Processing tab, you can see that the Melt temperature range (recommended) for the material is 180–260°C. The temperature of the flow front should not cause a weak point in the mold.

Parent topic: Post process options (tutorial)

Previous topic: Animate results

Next topic: Warpage