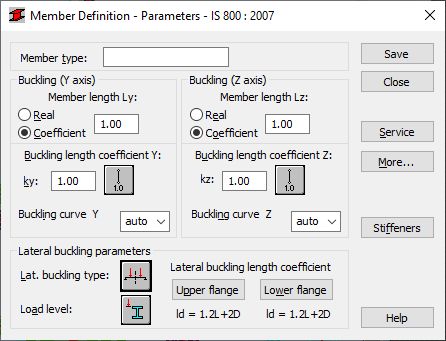

Use the Member Definition - Parameters dialog to define parameters of the member type for the Indian steel code IS 800: 2007. Open the dialog using either of the following ways:

- Click the New steel member definition icon in the Member type dialog

- Click the Parameters button in the Definition dialog.

The following parameters are defined in the dialog:

- Member Type: The name of a selected member type (you can enter any name of the member type to this field).

- Buckling (Y axis) or (Z axis): Defines the length of a member for the appropriate plane. There are two ways to define this length:

- Click Real, enter a value for the member length.

- Click Coefficient, enter a coefficient by which the real member length should be multiplied to obtain the required value. For instance, if the value 0.25 is entered, it means that the relevant length equals 1/4 of the real length. Use this method to define simultaneously several members whose real lengths differ, while additional supports, for example, are equally spaced. If you want to save the set parameters as a category, you must define the length this way. If you enter the value 1.0, then for each member that you defined as Ly using the category, Robot assumes its actual length.

- Buckling Length Coefficient (Ky and Kz): Defines member buckling length coefficients in both directions. The actual member length (or the sum of the component member lengths) is entered automatically to the appropriate fields.

- The buckling length coefficient depends on the end-support conditions of the member nodes in the buckling plane. The member buckling length may also be defined in the Buckling Diagrams dialog, opened by clicking the icon representing a selected type of the member buckling model. It includes typical diagrams of member support; when one is selected, Robot accepts or calculates automatically the coefficient value.

- The icons in the dialog are divided into two groups: the first one contains typical methods (based on codes) of supporting members and the corresponding values of buckling coefficients, while the other contains icons of options for calculating the buckling coefficient for columns of high-rise frames

- Buckling curve (Y and Z). Defines buckling curves. If you select auto, Robot chooses an appropriate buckling curve for the used section in accordance with requirements of the code; otherwise, Robot performs calculations assuming a user-defined buckling curve.

- Lateral Buckling Parameters (Lb and Cb): Defines the options used during verification of the lateral buckling of the member. You can access the options by clicking the relevant icon.

To perform lateral buckling calculations you need to specify the distance between cross-sections protected against torsion for a member, that is the lateral buckling length. You can distinguish 2 lateral buckling lengths because the upper or lower flange can be fixed separately and the compressive stress may occur in the upper or lower flange for different load cases. The dialog displays values of the coefficient by which to multiply the base member length to obtain the lateral buckling length. Robot assumes the length l as the base length. You can enter the coefficient value or select an icon representing a typical fixing case and the coefficient for it will be selected automatically.

Click the More button to access an additional dialog to define member type parameters specified in the code.

Click the Service button to open an additional dialog to define member type parameters (limit displacements, initial deflections).

Click Save to add a member type with the defined name and parameters to the list of previously defined steel member types.