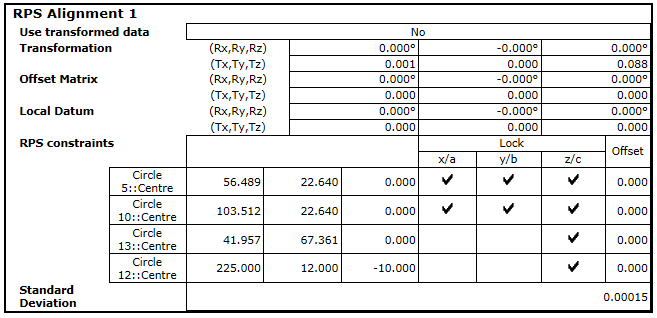

An RPS alignment is perfectly constrained when the minimum number of axis locks is used to fix the position and rotation of the part. In the following example:

the locking axes are assumed to be perfectly positioned, so the Report tab shows zero deviation for each item:

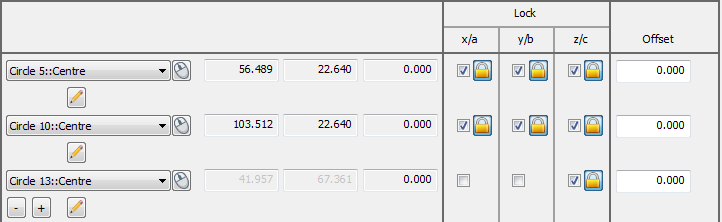

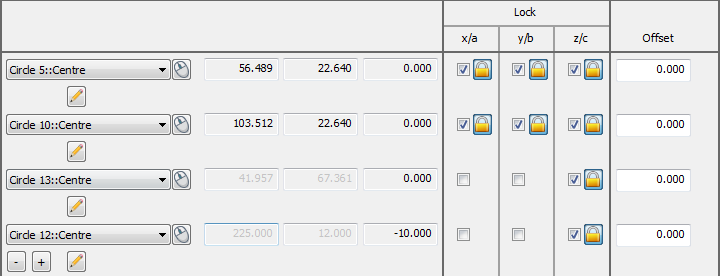

An RPS alignment is over-constrained when more than the minimum number of axis locks is used to fix the position and rotation of the part. In the following example, the alignment is over-constrained in the Z axis, so a best-fit algorithm is used to create the alignment:

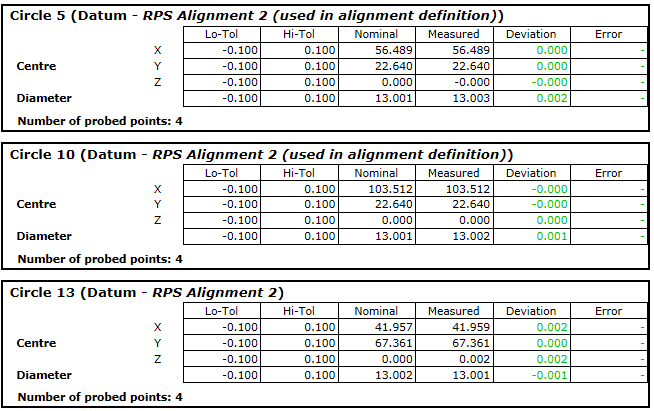

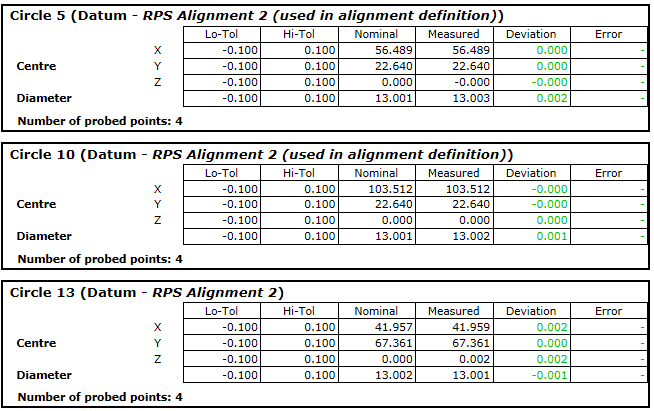

Because the Z axis is calculated from all the constraining items, the Report tab shows a non-zero deviation for the Z axis:

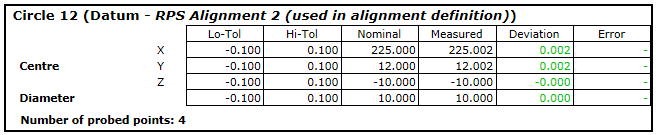

In addition, the Info tab, the Report tab, and the RPS Alignment dialog display the standard deviation of the measurements. For example: