Setting Objectives and Running Optimization

Understanding how to specify optimization objectives, change calculation iterations, and run your first surface optimization.

Learning Objectives

- Change the number of solving iterations.

- Specify the balancing and terrain smoothing objective weights.

- Initiate an optimization.

- Review and analyze the solution through the Convergence Plot.

- Conclude more constraints are necessary.

Open Grading Optimization

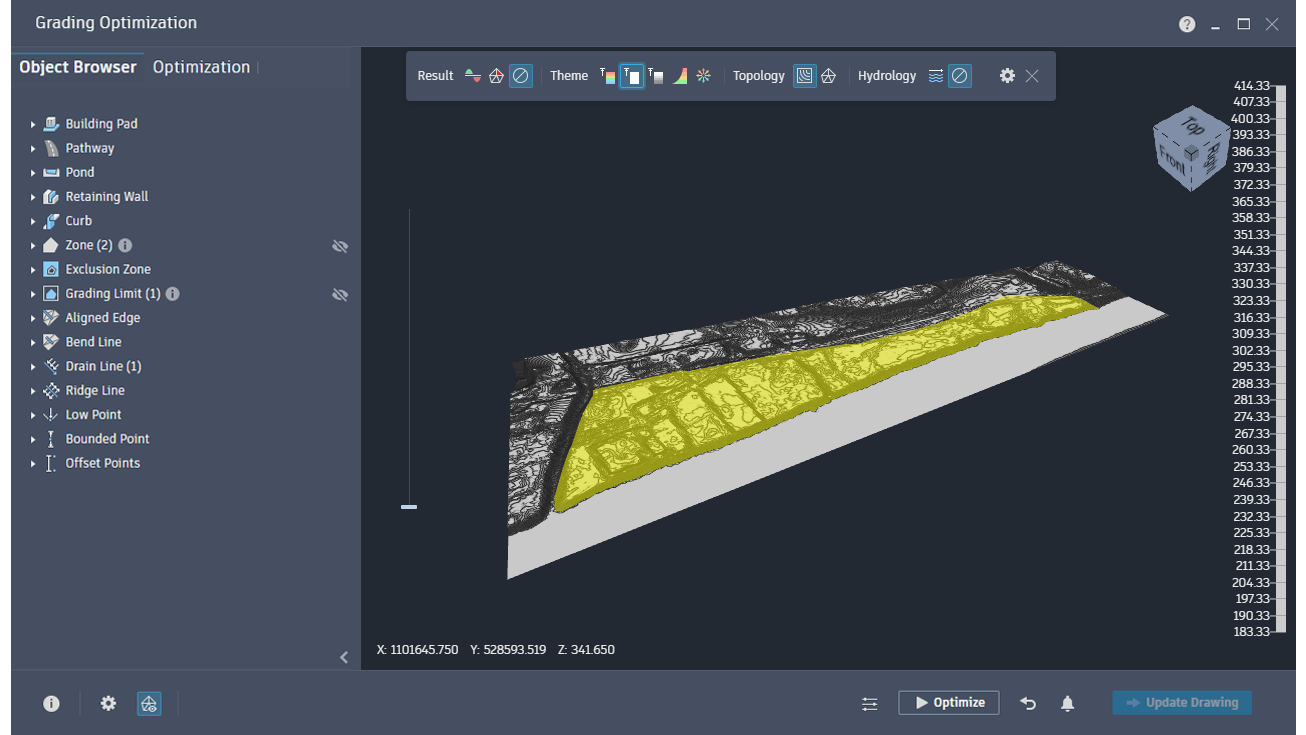

In the previous exercise, Creating Grading Limits, you specified a grading object and are now ready to open the object and its surface in Grading Optimization.

In Civil 3D, Click Analyze tab > Grading Optimization panel >  Optimize.

Optimize.

If multiple surfaces are in the drawing, you will be prompted to select the surface that you would like to use as the existing ground.

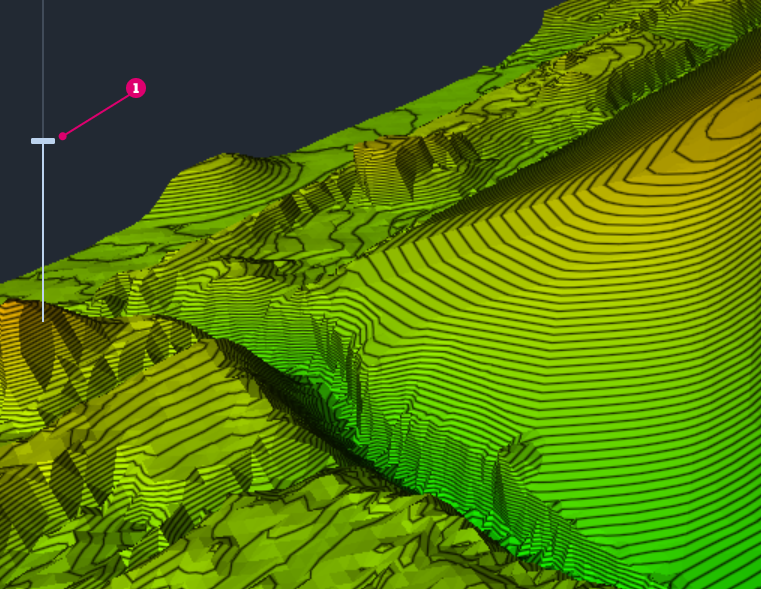

Grading Optimization opens. The surface and the Grading Limit object you previously created are displayed in the Visualization Display.

Specify Objectives and Solver Settings

You will now configure the objectives that were explored in the exercise, Optimization Constraints.

On the bottom right of Grading Optimization, on the Optimization Toolbar, click  Optimization Options to open the Optimization Options dialog.

Optimization Options to open the Optimization Options dialog.

Specify Global Constraints

The Global Constraint settings specify global slope constraints for both the maximum allowed slope, and the minimum required drain slope. These values are used in two specific situations:

- When a grading limit is not applied.

- When a zone lacks custom slope settings and has the Use global settings property enabled.

To make certain that a required minimum drain slope is not active on new zones added in the future, change that global setting to zero.

Specify Optimization Settings

The Optimization settings define the number of solver iterations will be calculated.

Limit the number of iterations to 25,000. This will terminate the solving process much earlier.

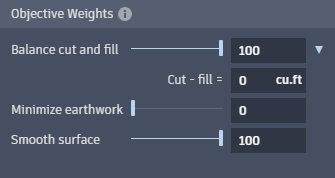

Define Objective Weights

You will now specify objectives as discussed in the exercise, Optimization Objectives. There are two main objectives for the mass grading:

- Terrain Smoothing

- Balancing cut and fill

In the optimization settings, you can specify the relative weights for each, on a scale from 0 to 100. To select a target balance volume, click the arrow to the right of Balance cut and fill.

For the purpose of this exercise, leave it at 0 cu.ft.

Give each objective equal weight and turn both to 100. Leave the earthwork minimization at 0, as you do not want to stay as close as possible to the existing ground.

When you have completed the optimization settings, close Optimization Options dialog.

Run an Optimization

Now, you will observe an optimization and prepare to analyze your grading settings.

On the bottom right of Grading Optimization, click  Optimize to begin the optimization.

Optimize to begin the optimization.

Notice that the solver starts changing the terrain contours in the Visualization display. Click  on either the Violation tab or Cut-fill tab of the Optimization Panel to open the Convergence Plots dialog.

on either the Violation tab or Cut-fill tab of the Optimization Panel to open the Convergence Plots dialog.

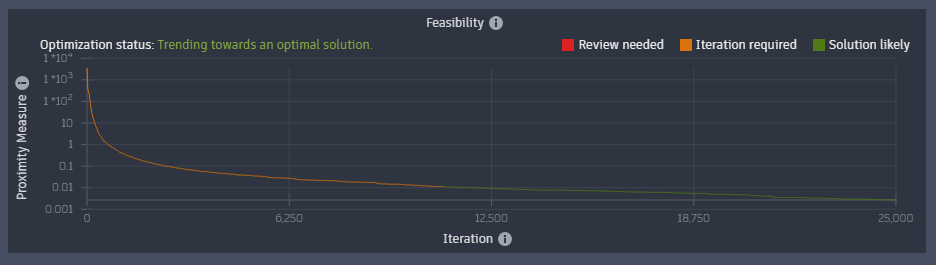

You can now observe how the optimization solver progresses as previously explained in Optimization Constraints. The following picture shows the feasibility plot after 25,000 iterations.

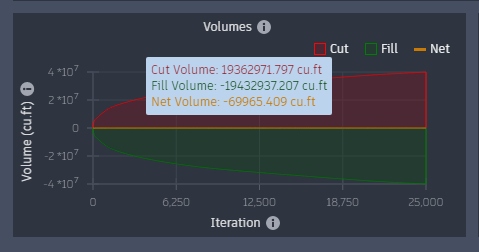

As the proximity value becomes smaller, notice that the solver is trending closer towards a feasible solution. Allowing this optimization to run longer, you can see the proximity value keeps moving towards zero. This indicates there is a unique feasible solution, which is also the best solution referencing the current objectives. The balancing plot shows a perfect balance.

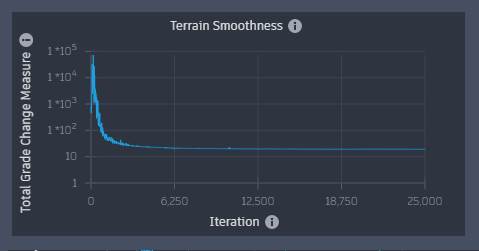

The cut and fill volumes are still growing as expected. Minimization of the earthwork is not required so the solver is creating more volumes to better smooth the surface and create contours that are more easily graded with machinery. The plot for terrains smoothing are also visible.

Analyze the Results

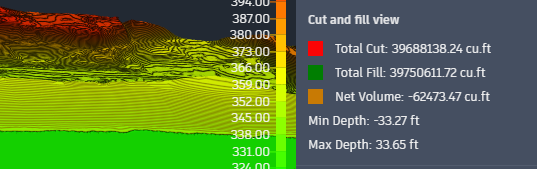

When looking at the final surface in the Grading Optimization Visualization Display, notice that the net volume is at -62,473 cubic feet, which corresponds to about -2,314 cubic yards.

Assuming a dump truck carries on average 15 cubic yards, 155 trucks of fill are required.

The contours on the surface show a hill on the left side that slopes the terrain down to the specified 33%. this is better visualized by exaggerating the elevations using the slider  to the left side of the Visualization Display.

to the left side of the Visualization Display.

This example exercise shows the process for analysis and how the objectives work. To produce a more viable mass graded site, you will need to go back and add more realistic constraints for the solver.