Using CAMduct, it is possible to use Common Line Cutting to reduce the cutting time of nested sheets/plates. This can also reduce the heat, and therefore distortion, created when cutting. This feature works best along straight edges.

To use Common Line Cutting in CAMduct:

- Create some relevant parts.

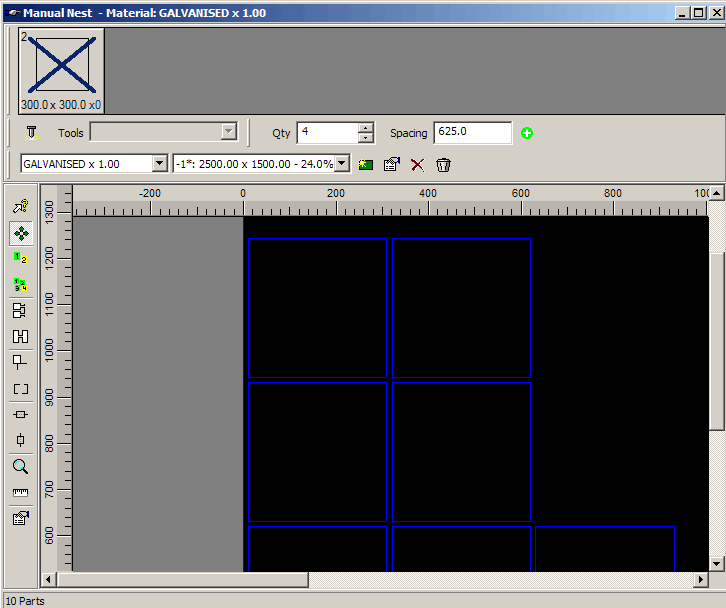

In this example, 10 plates 300mm x 300mm will be used.

- When these have been created, click Utilities

Automatic Nesting and the parts are nested.

Automatic Nesting and the parts are nested.

- Ensure the margin between parts is set as per the kerf value.

This would need to be the minimum value entered to allow for kerf compensation. Kerf values can be viewed from Installed Machines

Tools dialog. For example, a Kerf value of 1 must have a margin between parts set to at least 1.

Tools dialog. For example, a Kerf value of 1 must have a margin between parts set to at least 1.

- Note that the parts are nested with the margin between them, but will later be removed automatically when writing the NC with Common Line selected.

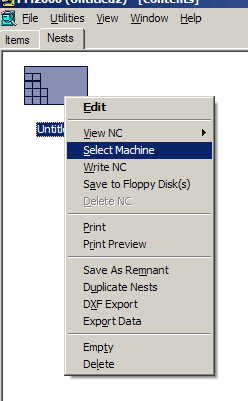

- Before the NC is written, select a single sheet, or drag a window around multiple sheets, and right-click.

- From the right-click menu, click Select Machine.

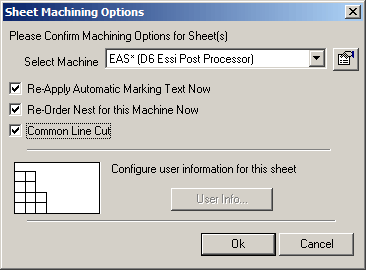

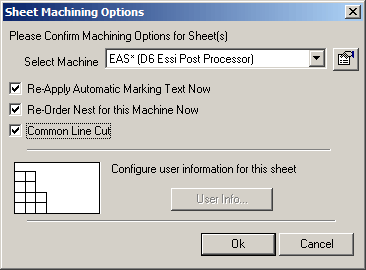

The Sheet Machining Options dialog displays.

- From the Select Machine drop-down menu, select the relevant machine.

- Make sure that the Common Line Cut option is selected.

- Click OK to return to the Job Contents dialog.

- Click Utilities

Write NC, and the following dialog displays.

Write NC, and the following dialog displays.

- Click OK.

The sheet(s) will now be assigned NC numbers.

Note: The sheets have now been nested and have had NC written that will ensure that the Common Line Cut method will be used.It is now possible to view the NC on the dialog before it is actually cut.

- Right-click on a relevant sheet and select View NC.

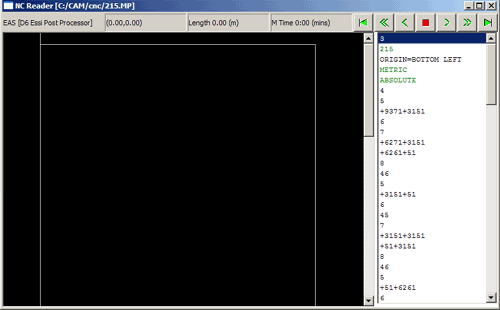

The NC Reader dialog displays.

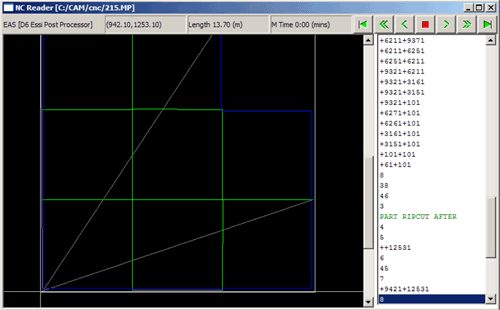

It is now possible to navigate through the NC data using the controls on the right.

This displays exactly what will be cut on the cutting machine.

Depending on the particular machine configuration, the completed NC data will be similar to the one below.

Note that there is no longer a margin between the nested parts, and that a 'common line' has been used to separate them.