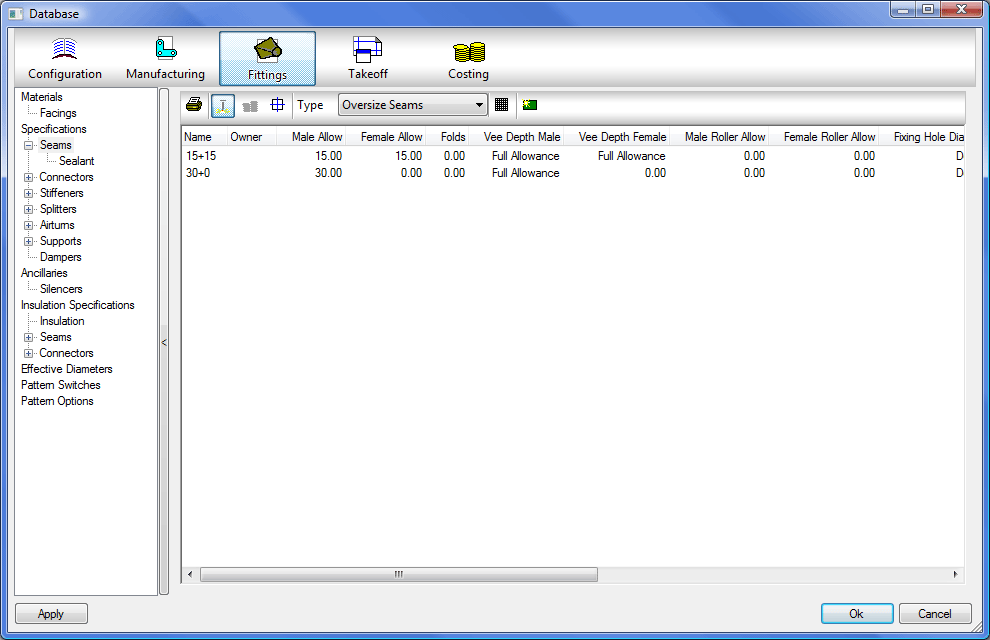

Pattern developments are often too large to fit onto the available sheet sizes. These pieces can be sliced into smaller parts interactively or automatically. Split parts are joined back together by oversize seams.

To create a new seam you can either:

- Right-click on the empty white space within the dialog window and selecting New.

- Click on the

button.

button.

To amend an existing seam, double click on the line containing the text. All these options will open up a dialog similar to the one shown below.

Name: A description of the seam.

Male Allowance: Applied to the female edge of the split part. When a part is manually split, the convention is that the male allowance is applied to the left of the split line relative to the direction in which it is drawn.

Female Allowance: Applied to the male edge of the split part.

Folds: The folds allowance is used to adjust the calculated length of heel and throat wrappers. This compensates for the number of material folds in the female part of the seam.

Vee Depth Male / Vee Depth Female: This is the depth of the V-notch used in developments.

Male Roller Allow / Female Roller Allow: The oversize seam may need to be notched back greater than the oversize seam allowance to allow clearance for machine rollers. The only time this is used as apposed to the roller allowance that can be defined in the seams and connectors is when a part is split two ways, so the oversize seam allowance is added on two sides of the part (i.e. where no connectors or normal seams apply).

Fixing Hole Diameter: This controls the hole size when Fixing Holes are required on the seam. If set to Default it will use the Hole Diameter size set up in the Database under Pattern Options - Fixing Holes. If a value is entered then this will be used when the Seam is applied to a fitting.

Hole Spacing: The Hole Spacing determines the distance between the hole centers when Fixing Holes are applied to a Seam. The user can enter a Value here or set it to Default which will pick up the values determined under Pattern Options - Fixing Holes.

Hole Inset: The Hole Inset determines the distance of the Hole Center, relative from the where the Seam is joined to the Body of the part. A Negative value will apply the hole onto the Seam Allowance, a Positive value will place the Hole on the Body of the part. The user can enter a Value here or set it to Default which will pick up the values determined under Pattern Options - Fixing Holes.

Allow holes one side only: There are 3 choices as to whether the Fixing Holes are applied to both sides of the seam or not. These are Yes, which will place the holes on one side of the seam only, No, which will place the holes on both sides of the Seam, and Default, which will apply the setting determined in the Pattern Options - Fixing Holes.

Male O/Seam Angle / Female O/Seam Angle: Cuts back the oversize seam to the required angle.

Notch: A Notch from the Notches database can be applied to the oversize seam.