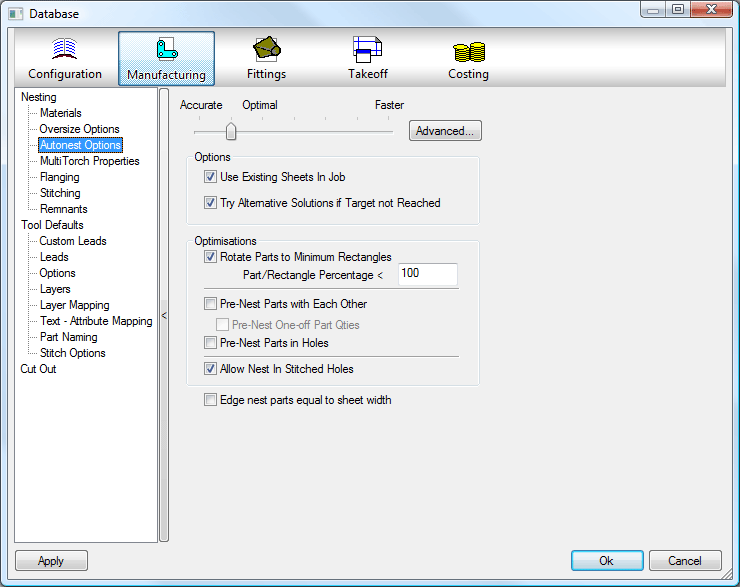

The Autonest Options dialog specifes the accuracy and method of Autonesting. These settings indirectly determine the amount of sheet wastage as the accuracy and speed of the nesting exist in a trade-off relationship.

The slider bar weights the nesting procedure between accuracy on the left and speed on the right. The positioning of this bar is therefore a guide to the efficiency of the whole procedure. An Accurate setting results in a tight nest, with the absolute minimum wastage considering processor speed. A Faster setting results in a less efficient nest, but completes the nesting procedure more quickly. The Optimal setting results in a balanced trade-of between the two extremes. If the nesting at this setting is not deemed accurate enough, the slider can be moved to the left. Alternatively, if the procedure is not considered fast enough, the slider can be moved to the right.

Options

Use Existing Sheets In Job: This option uses any empty "Untitled" sheets that already exist in the job, as long as the material and gauge correspond to the items being nested.

Try Alternative Solutions if Target not Reached: This option gives the auto nest function the opportunity to try several nesting combinations in order to achieve the best possible nest.

Optimizations

Rotate Parts to Minimum Rectangles: Rotating parts to minimum rectangles allows for some shapes to be squared off to the edge of the sheet. This is an advantage on a rectangular sheet.

Pre-Nest Parts with Each Other: Pre-Nesting attempts to create a rectangle from the parts on the sheet, and then nest these rectangles as entities themselves.

Pre-Nest One-off Part Qties: This tries to nest one off parts together. If this produces satisfactory results, the pre-nest is kept.

Pre-Nest Parts in Holes: Pre-Nesting in holes allows the procedure to place parts inside other parts, and keeps the combination together if the nesting appears to provide sheet economy.

Allow Nest In Stitched Holes: This allows parts to nest inside the stitched holes of larger parts.

Allow edge nest parts equal to sheet width: This option allows parts that are equal to the sheet width to be cut, where normally the part would be oversized. The edge of the sheet will then become the edge of the nested part. This is particularly useful for cutting straight duct that is equal to the sheet width, when a decoiler is not available.