There are many support types available for configuration. The support type that is selected impacts the calculations for quantities and lengths of the assigned materials.

Supports can be created and applied to specifications for automatic takeoff, or they can be associated with individual item files (using the "Support" field), allowing the item to be quantified with material and/or install time parameters.

All support types have the Breakpoints option, available on the lower left area of the Support dialog, as shown below. The Breakpoints option lets you select various materials based on the support size. Each type has its own method for calculation, as explained below.

Support Breakpoints

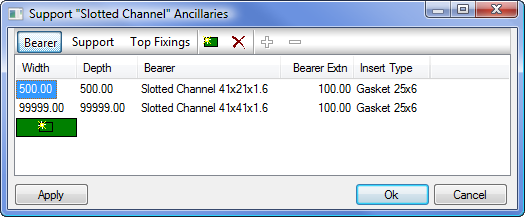

Each breakpoint entry includes the following three tabs: Bearer, Support and Top Fixings. The options below describe how the calculations occur, in terms of length or quantity.

Bearer Tab

The Bearer tab includes the following options:

- Width/Depth: Value entries which establish the number of breakpoints to be used across the three tabs. Adding an entry (row) here applies across all tabs. In terms of the application, a 500x500 breakpoint will apply to all sizes up to and including 500x500. Above this value of 501x501 uses the next breakpoint indicated in the example as 99999x99999. Multiple entries can be created to determine changes in the support options.

-

Bearer: This is for Ancillary Material assignment. A Material must be assigned with the correct costing parameter (per m value) in order for this to be displayed in the Cost Breakdown. The length of the Bearer is dictated by the type selected, but commonly the width of the item if Rectangular/Oval or the circumference if using Round/Pipe.

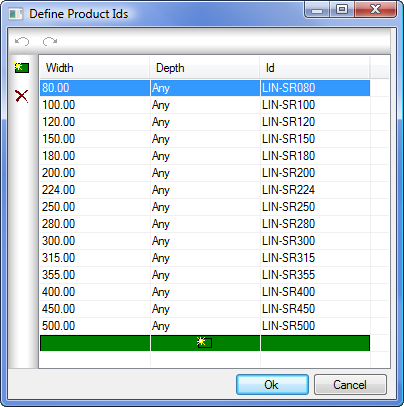

For product listed supports, the ancillary material can have a code-based reference for each size by using the Product Ids option on the Ancillary Material creation dialog.

When defining the sizes and codes from the Product Ids option, the Product Id field on the Ancillary Material will automatically display a Breakpoints value to show that this has breakpoints assigned.

The code for each diameter can be linked to a code-based price list, which must be costed per m for each of the sizes for example to enable calculation for circumference length.

- Bearer Extn: The Bearer Extn field is a custom value extension that is added to the total length of the bearer. Commonly used to accommodate for the Rod fixings and is dependant on the type of Support being costed.

- Insert Type: Provides the ability to assign additional material to the underside of the item and acts as the material between item and bearer. This is created in the Ancillary Materials section and assigned using the drop-down box. Whether this is used depends on the Support type again, but commonly the insert can be priced per m. An example would be the Width of the duct for Rectangular/Oval or Circumference/2 if Round/Pipe.

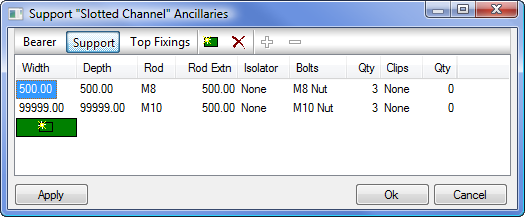

Support Tab

The Support tab includes the following options:

-

Width/Depth: Value entry which establishes the number of breakpoints to be used across the three tabs. Adding an entry (row) here applies across all tabs. In terms of the application, a 500x500 breakpoint will apply to all sizes up to and including 500x500. Above this value of 501x501 uses the next breakpoint, indicated in the example as 99999x99999.

-

Rod: Specifies a Support Rod Ancillary. Support Rod Ancillary must be created from the Ancillaries database. If using Profile Bearer type, this is a length-based output initially from the depth of the item being supported. For example, a 600x400 rectangular duct would have a default Rod length of 400mm. A 250 diameter pipe would have a default 250mm Support Rod allocated.

-

Rod Extn: Specifies the additional length of Rod required to be added to the Rod length. Item Depth + Rod Extn = Total length of Rod. Multiple rods will get extensions for each. Again, this is dictated by the type of support selected as to whether it is applied.

-

Isolator: Created from the Support Isolators Ancillary. A cost per Quantity can be assigned per Rod application.

-

Bolts/Qty: Ancillary Fixings can be assigned and specified a quantity for application onto the Support cost.

-

Clips/Qty: Can specify additional Ancillary Fixings for Clips.

Top Fixings Tab

The Top Fixings tab includes the following options:

-

Width/Depth: Value entries which establish the number of breakpoints to be used across the three tabs. Adding an entry (row) here applies across all tabs. In terms of the application a 500x500 breakpoint will apply to all sizes up to and including 500x500. Above this value of 501x501 uses the next breakpoint indicated in the example as 99999x99999.

-

Top Fixings (Undefined)/Alternative: If using Top Fixings, the default would be undefined which uses the Fixing ancillary listed in the drop-down for that column. Multiple Fixing types can be created from the Ancillaries database

Fixings.

Fixings.

-

Plus and Minus Buttons: Different types of fixing can be defined for different structures that the supports will be fixed to. Clicking the plus (+) button, located at the top of this dialog, adds a new type in which you can select an alternative Fixing type from the available structures. Clicking the minus (-) button displays a list of any existing structures used for deletion. The Structures are setup in the Structure Types section of the Services Database. Each service can be set to use a particular Structure type at takeoff. For more information, see Structure Types.

Support Types Defined

Each type is listed here, along with which ancillaries report out when they are assigned to the breakpoint fields.

PROFILE BEARER

For use with Slotted Channel, Rolled Steel Angle. Pattern Group: RECT,OVAL. A BR tag was used here in the original source. Most commonly used with Rectangular ductwork. The Profile Bearer type comes with 2 rods on either side, and a bearer holding the duct from the underside.

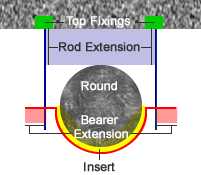

The sample illustration above includes color-coded areas that are described below.

Bearer: Costed per meter and the length is calculated by the width of the item plus Bearer Extensions indicated by the Pink region.

Rods: Each costed per meter and the lengths are calculated by the depth of the item plus the Rod Extension for each rod indicated by the Pale Blue region.

Top Fixings: Costed per quantity and calculated on the quantity of Rods required.

Insert Type: Costed by the item width and is length based isolators.

Fixings: Costed by single quantities.

Clips: Costed by single quantities.

STIRRUP

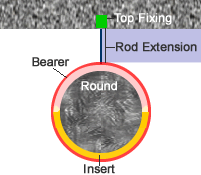

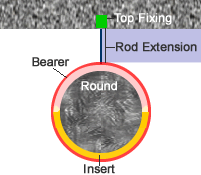

For use with: Split Rings, Suspension Rings. Pattern Group: ROUND,RECT,OVAL. Commonly used for Round ductwork or Pipework hangers. The Stirrup type has 2 rods with half diameter bearer.

The sample illustration above includes color-coded areas that are described in the following definitions.

Bearer Costed per meter and the length is calculated by the item circumference divided by 2 plus Bearer Extensions indicated by the Pink region .

Rods Each costed per meter and the lengths are calculated by the depth of the item plus the Rod Extension for each rod indicated by the Pale Blue region.

Top Fixings Costed per quantity and calculated on the quantity of Rods (2).

Insert Type Costed by the item width and is length based. Round is costed (Diameter x Pi ) / 2. Isolators

Fixings Costed by single quantities.

Clips Costed by single quantities.

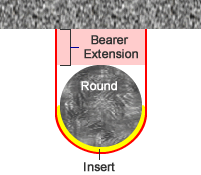

WRAP ROUND HANGER

For use with: Gripple. Pattern Group: ROUND. Used for a complete wrap around of the circular item only. This uses the Rod length for its calculation meaning the circumference plus Rod extension.

The sample illustration above includes color-coded areas that are described in the following definitions.

BearerNo Bearer cost used as its calculated by the Rod field completely.

RodsCosted per meter in place of the Bearer in which the length is calculated for the circumference plus the Rod Extension , indicated by the Pale Blue region.

Top Fixings Costed by a single quantities.

Insert Type Costed by half the item circumference which is a length based cost and then halved. (Diameter x Pi ) / 2.

Fixings Costed by single quantities.

Clips Costed by single quantities.

FLAT STRAP HANGER

For use with: Gripple. Pattern Group: ROUND,RECT,OVAL. Used for a complete wrap of the item in which there is no Rod application.

The sample illustration above includes color-coded areas that are described below.

Bearer: Costed per meter. The length is calculated dependant on shape, For Round, (Circumference / 2) + (Radius X 2) + ( Bearer Extension X 2). For Rectangular, (Duct Depth X 2) + Width + ( Bearer Extension X 2);

Rods: No Rods used .

Top Fixings: No Top Fixing.

Insert Type: For Round, Costed by half the item circumference which is a length based cost.(Diameter x Pi ) / 2. For Rectangular, Costed by the item periphery and is length based (Width+Depth+Width+Depth).

Fixings: Costed by single quantities.

Clips: Costed by single quantities.

FULL WRAP HANGER

Pattern Group: ROUND. Used for a complete wrap of the item in which there is no Rod application.

The sample illustration above includes color-coded areas that are described below.

Bearer: Costed per meter. The length is calculated by the item circumference only, with no Bearer Extensions.

Rods: Costed per meter in which the length is calculated by the Rod Extension only, indicated by the Pale Blue region.

Top Fixings: Costed by single quantities.

Insert Type: Costed by half the item circumference which is a length based cost.(Diameter x Pi ) / 2.

Fixings: Costed by single quantities.

Clips: Costed by single quantities.

CLIPPED FLAT STRAP HANGER

Pattern Group: ROUND. Consists of two straps that go around the fitting and extend at the top and bottom for fastening.

The sample illustration above includes color-coded areas that are described in the following definitions.

Bearer: Costed per meter. Bearer length is calculated by the circumference plus four times the Bearer Extensions indicated by the Pink region.

Rods: Costed per meter in which the length is calculated by the Rod Extension only, indicated by the Pale Blue region.

Top Fixings: Costed by single quantities.

Insert Type: Costed by half the item circumference which is a length based cost and then halved. (Diameter x Pi ) / 2.

Fixings: Costed by single quantities.

Clips: Costed by single quantities.

CLEVIS HANGER

Pattern Group: ROUND,RECT,OVAL. Used for a complete wrap of the item in which there is no Rod application.

Bearer: For Round, no Bearer cost used as it is calculated by the Rod field only. For Rectangular, Duct Width plus Extensions either side Width + (Bearer Extension X 2)

Rods: Costed per meter calculated by the Rod Extension only.

Top Fixings: Costed by a single quantities.

Insert Type: For Round, Costed by half the item Circumference which is a length based cost.(Diameter x Pi ) / 2. For Rectangular, Costed by the item Width and is length based.

Fixings: Costed by single quantities.

Clips: Costed by single quantities.

ROLL CLEVIS HANGER

Pattern Group: ROUND, RECT, OVAL. Used for a complete wrap of the item in which there is no Rod application.

Bearer: For Round, No Bearer cost used as its calculated by the Rod field only. For Rectangular, Duct Width plus Extensions either side Width + (Bearer Extension X 2)

Rods: Costed per meter calculated by the Rod Extension only.

Top Fixings: Costed by a single quantities.

Insert Type: For Round, Costed by half the item Circumference which is a length based cost.(Diameter x Pi ) / 2. For Rectangular, Costed by the item Width and is length based.

Fixings: Costed by single quantities.

Clips: Costed by single quantities.

FLOOR/ROOF SUPPORT

Pattern Group: ROUND,RECT. Used for a complete wrap of the item in which there is no Rod application.

Bearer: For Round, No Bearer cost used as its calculated by the Rod field only. For Rectangular, Duct Width plus Extensions either side Width + (Bearer Extension X 2)

Rods: Costed per meter calculated by the Rod Extension only.

Top Fixings: Costed by a single quantities.

Insert Type: For Round, Costed by half the item Circumference which is a length based cost.(Diameter x Pi ) / 2. For Rectangular, Costed by the item Width and is length based.

Fixings: Costed by single quantities.

Clips: Costed by single quantities.

DOUBLE FLOOR/ROOF SUPPORT

Pattern Group: ROUND,RECT. Used for a complete wrap of the item in which there is no Rod application.

Bearer: For Round , No Bearer cost used as its calculated by the Rod field only. For Rectangular, Duct Width plus Extensions either side Width + (Bearer Extension X 2).

Rods: Costed per meter calculated by the Rod Extension only.

Top Fixings: Costed by a single quantities.

Insert Type:For Round, Costed by half the item Circumference which is a length based cost.(Diameter x Pi ) / 2. For Rectangular, Costed by the item Width and is length based.

Fixings: Costed by single quantities.

Clips: Costed by single quantities.