The information below describes one example of how to setup a decoiler. In this example, a Forstner decoiler is used.

In this example, the machine has two decoiler lines: Line 1 which is 2000,mm wide, and Line 2 which is 3000mm wide. Line 2 is at right angles to Line 1 and is used to make non-standard length straights. There are two standard lengths (1500 and 1840mm), and five coils feed different materials to the lines.

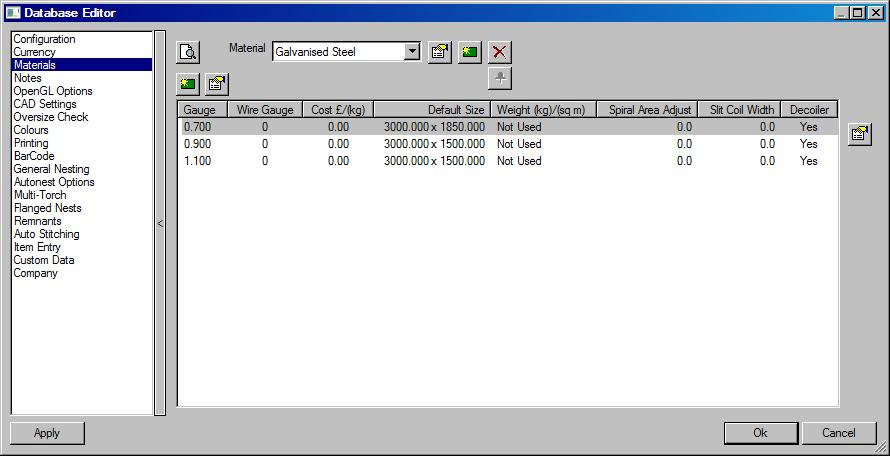

Main Database

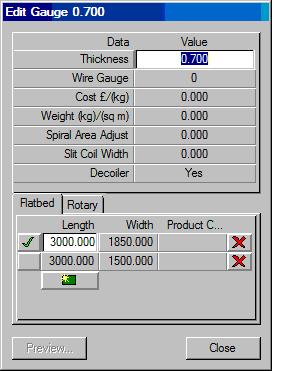

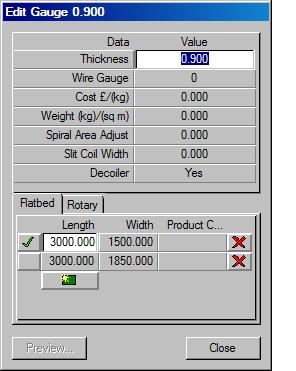

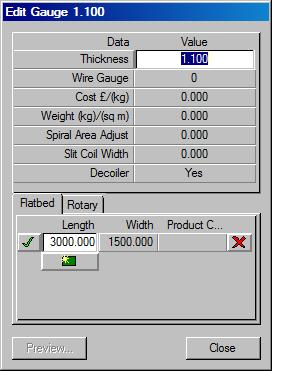

Set a material with the coil thicknesses required for use with the Forstner decoiler.

For each material thickness, create the width required for use with the Forstner decoiler.

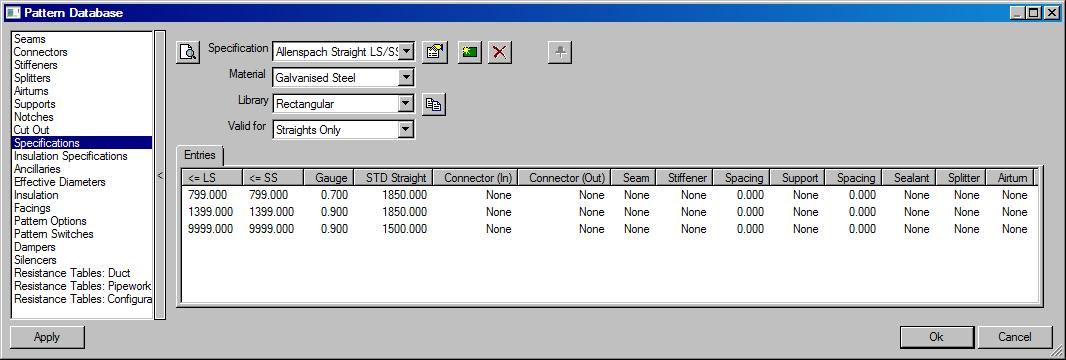

Pattern Database - Specifications

Set up specifications that will create straight items suitable for use with the decoiler.

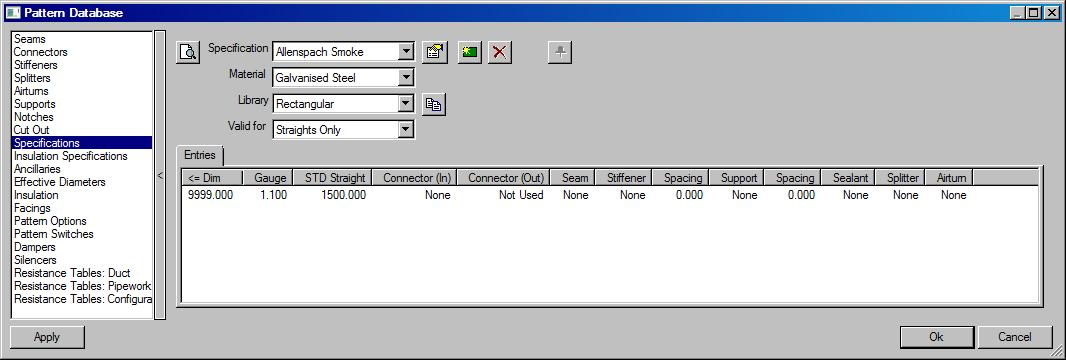

Pattern Database - Pattern Options - Straights

Set up the Straight options similar to what is shown below to allow the decoiler to use the two coils widths of 1500 and 1850 for standard straights. These will be made on Line 1. Straights that do match the two standard lengths will be made on Line 2.

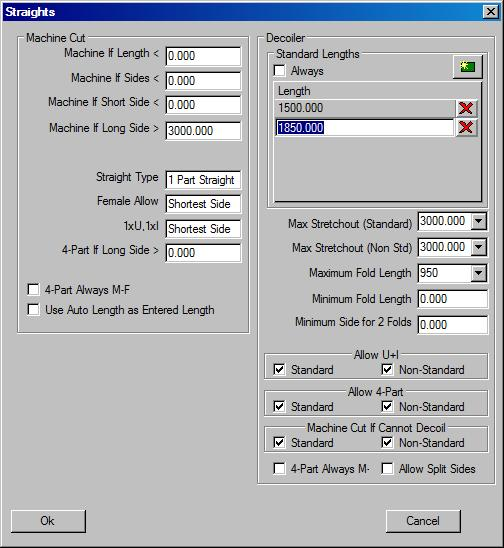

Installed Decoiler

Main Tab

Setup a decoiler that uses decoiler post processor FORSTERNDPL.DPL. Click on the Browse button to locate the decoiler post processor file.

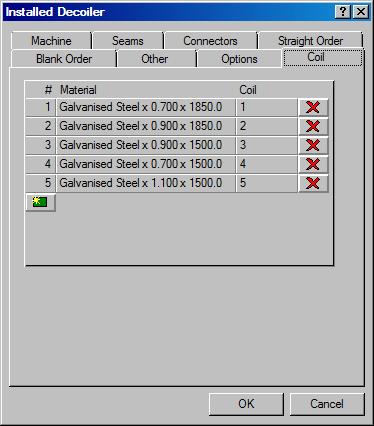

Coil Tab

This decoiler post processor supports the new Coil allocation tab. Use the Coil tab to allocate coil numbers to the materials that will be used with the decoiler.

The Coil value will be output in the "Tisch" field in the ASCII file.

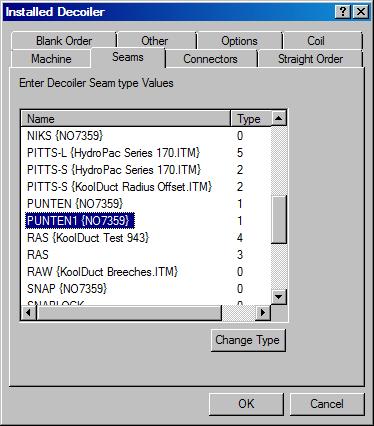

Seams Tab

Each seam can have a Type value in the range of 0.8.

The Type value will be output in the "FaType" field in the ASCCI file. If the Type value is 0, the Male and Female Seam Allowances will be output in the "FaZu Anf" and "FaZu Ende" fields.

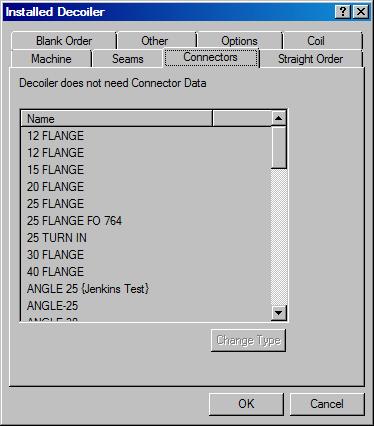

Connectors Tab

This tab has no effect with the Forstner post processor.

Straight Order Tab

This tab controls the order in which the straight items will be output in the ACSII file.

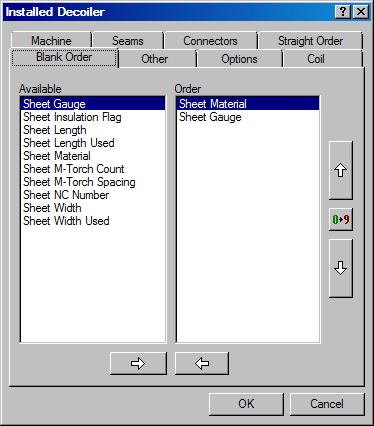

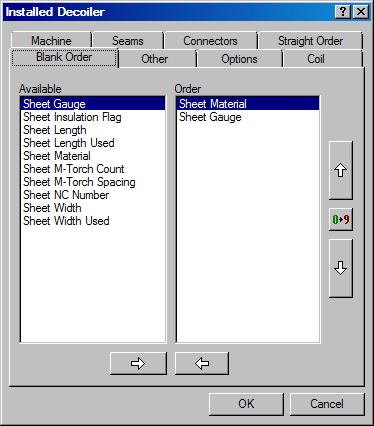

Blank Order Tab

If the decoiler is being used to cut sheet blanks for use on a cutting machine, this tab controls the order in which the sheet blanks will be output in the ASCII file.

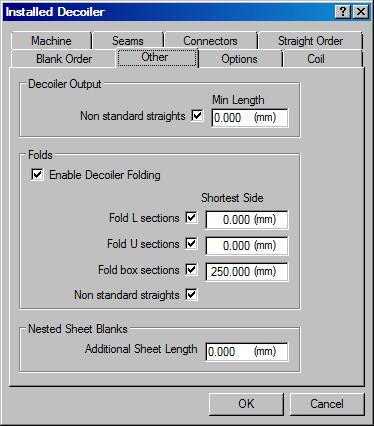

Other Tab

This is primarily used to control the folding options for the various duct section types. For the Forstner decoiler, the box sections must be at least 250mm to allow the former to create the duct section.

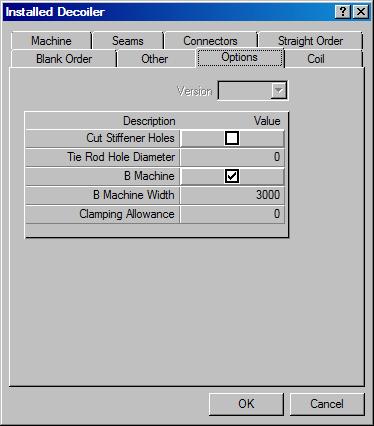

Options Tab

This tab is used to control machine specific options. For the Forstner decoiler, the two most import options are the B Machine option, which enables the use of the second line, and the B Machine Width option, which should be set to the width of the 2 second line. The second line is normally used for making standard length straights.

Example of a file:

xxx,1,00350.0,00300.0,02000.0,0000.0,0000.0,0000.0,002,001,2,0,1,0,0,0,0,0,0,0,0,0,024.0,012.0,0,1,0,1,1;

|

Tisch |

A |

B |

L-Ka/B-Ta1 |

B-Ta2 |

B-Ta3 |

B-Ta4 |

Menge |

Menge-L2 |

Typ |

|

| xxx, | 1, | 00350.0, | 00300.0, | 02000.0, | 0000.0, | 0000.0, | 0000.0, | 002, | 001, | 2 |

| 1 | 5 | 7 | 15 | 23 | 31 | 38 | 45 | 52 | 56 | 60 |

|

Vw MeBl |

Vw Ka-L |

Vw Ta1 A |

Vw Ta2 A |

Vw Ta2 A |

Vw Ta2 A |

Vw Ta1 B |

Vw Ta2 B |

Vw Ta3 B |

Vw Ta4 B |

|

0, |

1, |

0, |

0, |

0, |

0, |

0, |

0, |

0, |

0, |

|

62 |

64 |

66 |

68 |

70 |

72 |

74 |

76 |

78 |

80 |

|

FaTyp |

FaZu Anf. |

FaZu End |

Fa Bieg |

Prof. A1 |

Prof. B1 |

Prof. A2 |

Prof. B2 |

||

|

0, |

024.0, |

012.0, |

0, |

1, |

0, |

1, |

1; |

||

|

82 |

84 |

90 |

96 |

98 |

100 |

102 |

104 |

Interpretation:

Table = 1,

Length A = 350.0 mm,

Length B = 1000,0 mm,

Länge Kanal=2000,0mm,

Breite Tafel B2=0,0mm,

Breite Tafel B3=0,0mm,

Breite Tafel B4=0,0mm

Number = 2,

Anzahl Linie 2=1,

Type = 2 (Duct 2 L)

Mehrblech=0 (nur 1 Kanal aus einem Zuschnitt)

Kanal-L=1 (mit Vorgabe Kanallänge)

Vorwahlen Tafel Bx=0

Fold type = 0 (it will be given Fold allowance used)

Fold allowance start= 24.0 mm

Fold allowance end = 12.0 mm

Fold bending at the start = no

Profiling side A1 = yes, B1 = no, a2 = yes, B2 = yes;