Splitter vanes, also known as splitters, are required by some ductwork specifications to assist the air flow around bends. In the Autodesk Fabrication products, splitters can be applied to several of the radius elbow and breeches (pants) patterns.

A variety of manufacturing and costing settings can be specified for splitters, as described below.

Manufacturing Settings

To specify the manufacturing settings for a splitter:

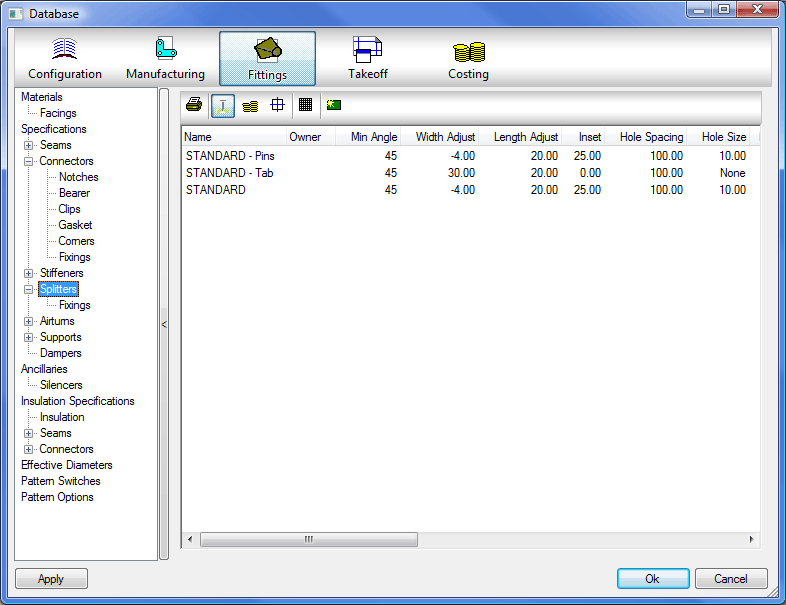

- Click Database

Fittings

Fittings

Specifications

Specifications

Splitters.

Splitters.

- On the Splitters database dialog, click the Manufacturing button

to ensure that Manufacturing settings are enabled (displaying in the database dialog).

to ensure that Manufacturing settings are enabled (displaying in the database dialog).

- To create a new entry, right-click and choose New or click

.

.

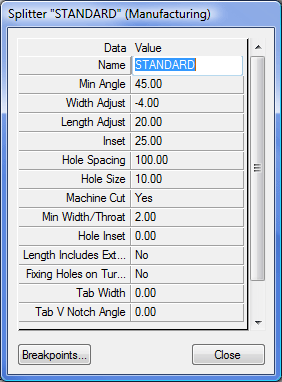

- Double-click an entry in the database dialog (table) to change the values.

When you do this, the Manufacturing properties dialog for the splitter displays, similar to the one shown below.

The following Manufacturing properties are available for splitters.

Name: This field lets you specify a description to identify the splitter.

Min Angle: Enter the Minimum Bend Angle greater than and including the value at which splitters are required. Typically this will be 45, 75 or 89 degrees.

Length Adjust: The calculated Vane Length can be adjusted for an allowance that can be rolled over to form a safety edge. This value is added to or subtracted from the Vane Length.

Inset: Specifies the inset from the radius point at which the vane will start.

Hole Spacing: If splitter vane fixing holes are to be marked or cut, enter the value for the hole spacing.

Hole Size: The options are:

- Pierce: The plasma torch will pierce at the hole center.

- Mark: The marker tool will mark the center of the hole.

- Value: Enter the diameter of the hole to be cut.

Machine Cut: Specifies whether or not the splitter is machine cut or not.

Min Width/Throat: Specifies a minimum size that the width/throat must be before splitters are required. Note that the width/throat is a ratio. For example, if the width is 600, and the throat radius is 300, then the ratio is 2. Therefore, in this case, splitters are not required, and would not be applied. When this parameter is set to 2, if the throat is 250, then the ratio would be 600/250 or 2.4. Therefore, in this case, splitters would be applied.

Hole Inset: Specifies the distance from the edge of the splitter that the first and last hole will be.

Length includes Extensions: This can be set to Yes or No. When set to Yes, the Length for the splitter is measured including any extensions. When set to No, the Length for the splitter does not include any extensions.

Fixing Holes in Turnover: This field determines whether or not fixing holes will be placed in the turnover or not.

Omit Centre Hole If End Holes Closer Than Spacing: When this option is set to Yes, the center fixing hole for the splitter is omitted if the distance between the 2 end holes is less than the hole spacing. To verify that this setting is configured as desired, and that the center hole is removed, the length of the splitter arc should be smaller than hole spacing, so that holes exist at the ends only. The easiest way to do this is to either decrease the bend angle, or increase the hole spacing and inset.

Tab Width: This field specifies the width of the tabs, if they are used, on the turnover.

Tab Vee Notch Angle: This field allows the user to set the angle of the vee notch that will be placed in the turnover.

Tab Length: This determines the length of the tab along the splitter.

Tab Quantity: This allows the user to determine the quantity of tabs on the splitter. If left at 0, it will add tabs along the full length of the splitter. A value places the tabs equally along the splitter.

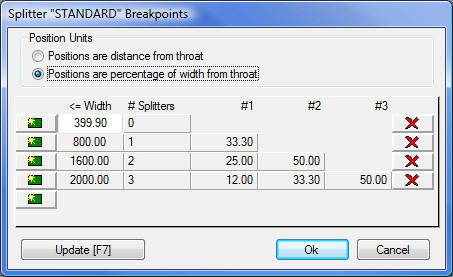

Breakpoints: Once the above properties are set, the next step is to apply breakpoints to the splitter. Creating breakpoints allows different amounts of splitters to be produced for different widths of duct. Click on the Breakpoints button to display the Breakpoints dialog.

Position Units: Two methods for calculating splitter spacing are available when you click the Breakpoints tab. Choose the method required.

Positions are a distance from the throat: When this option is used the vane positions entered for fields #1, #2, and #3 are absolute distances from the center of Bend Radii. The <=Width (less than or equal to) field will determine when the breakpoint will be applied. In the example above, a duct width a width of less than 399.9mm, will not have splitters applied. A duct with a width of less than 800 but greater than 399.9 would get 1 splitter.

Positions are a percentage of the Duct Width from the throat: When this option is used, the vane positions entered for fields #1, #2, and #3 are percentages of the Duct Width taken from the center of the Bend Radii. The <=Width (less than or equal to) field will determine when the breakpoint will be applied, as explained above. In this case however, the figures input in the 3 fields would normally be around 50% for 1 splitter, 33.3% and 66.6% for 2 splitters, and 25%, 50% and 75% for 3 splitters.

Estimating Settings

To specify estimating (costing) information for splitters:

- Database

Fittings

Fittings

Specifications

Specifications

Splitters

Splitters

- On the Splitters database dialog, click the Estimating button

to ensure that Estimating settings are enabled (displaying in the database dialog).

to ensure that Estimating settings are enabled (displaying in the database dialog).

- To create a new entry, right-click and choose New or click

.

.

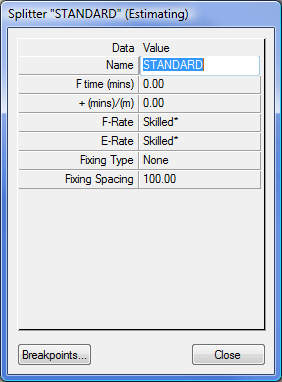

- Double-click an entry to change the values.

When you do this, the Estimating properties dialog for the splitter displays, similar to the one shown below.

The following Estimating properties are available for splitters.

Name: Lets you specify a description to identify the splitter.

F-time (mins): Specifies the time required to manufacture the splitter.

+(mins)/m: This option specifies the number of minutes that can be added to the fabrication time per meter (or feet) of splitter material. This option allows you to adjust (increase) the fabrication time relative to the length of the splitter material.

F-Rate: Specifies the Fabrication rate for this splitter. The available settings are Unskilled, Low Skilled, Skilled, and High Skilled. The values for these rates are set in the Costing Database, in Sections and Rates.

Fixing Type: From the drop-down menu, you can view the fixing types entered in the Ancillary settings.

Fixing Spacing: This represents the distance between the splitters and is used in calculating the number of splitters required.

Breakpoints: Click on the Breakpoints button to access the Breakpoints dialog. See the information on Breakpoints described above.